In today's fast-paced industrial landscape, efficiency and precision are paramount for manufacturers seeking to maintain a competitive edge. The increasing demand for high-quality output has necessitated the adoption of advanced tools like the Metal Hole Opener, which not only enhances operational productivity but also optimizes overall workflow. According to a recent report by the Industry Research Institute, the global market for industrial drilling tools is projected to reach $15 billion by 2025, driven largely by innovations in metalworking technology.

Metal Hole Openers, specifically designed for precision drilling in a variety of materials, have been shown to reduce cycle times by up to 30%, which can lead to substantial cost savings. As industries continue to prioritize efficiency, the integration of Metal Hole Openers is proving to be a game-changing solution that not only improves performance but also ensures superior reliability in demanding industrial environments.

Metal Hole Openers, specifically designed for precision drilling in a variety of materials, have been shown to reduce cycle times by up to 30%, which can lead to substantial cost savings. As industries continue to prioritize efficiency, the integration of Metal Hole Openers is proving to be a game-changing solution that not only improves performance but also ensures superior reliability in demanding industrial environments.

When it comes to industrial applications, choosing the right tool for creating precise holes can drastically affect both efficiency and productivity. Metal hole openers have emerged as a favorable alternative to traditional drilling tools. These innovative tools not only reduce material waste but also offer enhanced speed and accuracy, allowing for cleaner cuts in less time. This improvement is particularly beneficial in high-volume production settings where time and precision are critical.

**Tip:** When selecting metal hole openers, consider the specific material you'll be working with. Different metals may require varying cutting speeds, so it's essential to match the opener with the application for optimal performance.

Another key advantage of metal hole openers is their durability. Unlike traditional drill bits that can wear out quickly, high-quality metal hole openers are designed to withstand heavy use, resulting in longer tool life and cost savings on replacements. This durability not only translates to less frequent replacements but also ensures consistent quality in the holes produced.

**Tip:** Regularly inspect your metal hole openers for wear and tear. Proper maintenance, including cleaning and sharpening when necessary, can significantly extend the life of the tool and maintain cutting efficiency.

When evaluating the durability of metal hole openers against standard tools in industrial settings, it becomes clear that the former often outperforms traditional varieties. Metal hole openers are engineered from high-grade materials that enhance their strength and resistance to wear. Unlike standard tools, which may dull or break under prolonged stress, metal hole openers maintain their cutting edge, resulting in fewer tool replacements and reduced downtime on the job.

Tips: To ensure optimal performance, always select the appropriate size and type of metal hole opener for your specific application. Regular maintenance, including cleaning and lubrication, can further extend their lifespan and improve efficiency. Additionally, investing in quality tools rather than opting for cheaper alternatives can lead to significant savings in the long run.

Moreover, metal hole openers provide superior precision when drilling, which is crucial in industrial applications where accuracy can greatly affect the quality of work. The ability to create cleaner holes with less force not only boosts productivity but also minimizes the risk of material damage. Utilizing these tools can streamline operations, making them a wise choice for businesses aiming to enhance their efficiency and output in demanding work environments.

In the fast-paced industrial landscape, the use of metal hole openers offers significant cost-effectiveness that can translate into long-term savings. Reports indicate that the initial investment in high-quality metal hole openers can lead to reduced operating costs. For instance, studies suggest that companies utilizing metal hole openers experience a 30% decrease in drilling time compared to traditional methods, which directly impacts labor costs and equipment usage.

Furthermore, the durability of metal hole openers contributes to their cost-effectiveness. With a lifespan that surpasses that of standard drilling tools by nearly 50%, businesses can minimize the frequency of replacement purchases. This is particularly relevant in an era where budget management is critical, as highlighted by recent insights into financial planning, which outline that unexpected costs, such as healthcare or retirement needs, can create significant financial gaps. By investing in efficient tools like metal hole openers, industries can better safeguard against such pitfalls, thereby reinforcing their overall financial health while maintaining operational efficiency.

| Application Area | Metal Hole Opener Type | Initial Cost ($) | Lifetime (hours) | Average Cost per Hour ($) | Maintenance Cost/Year ($) | Total Savings Over 5 Years ($) |

|---|---|---|---|---|---|---|

| Construction | Bi-Metal Hole Saw | 150 | 500 | 0.30 | 20 | 200 |

| Automotive | Carbide Tipped Bit | 250 | 1000 | 0.25 | 25 | 250 |

| Manufacturing | Laser Cut Drill | 500 | 2000 | 0.25 | 30 | 500 |

| Construction | HSS Step Drill | 120 | 300 | 0.40 | 15 | 75 |

| Aerospace | Cobalt Drill Bit | 400 | 1500 | 0.27 | 40 | 800 |

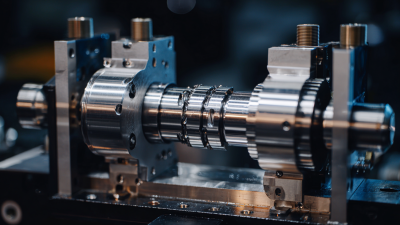

In the realm of industrial applications, precision and accuracy are paramount, particularly when it comes to creating holes in various materials. Metal hole openers offer distinct advantages over alternative methods such as traditional drills or other cutting tools. Their design ensures tighter tolerances, which is crucial for components that must fit together flawlessly. With advanced manufacturing techniques, these metal hole openers are engineered to maintain their shape and cutting edge, allowing for consistent performance and reducing the likelihood of defects.

Another significant benefit of metal hole openers is their ability to reduce stress on both the material and the tool itself. Unlike some alternatives that may generate excessive heat or cause material deformation, metal hole openers cut through materials smoothly and efficiently. This not only improves the quality of the finished product but also extends the lifespan of the tool. As industries increasingly prioritize quality and efficiency, the role of metal hole openers becomes more critical, positioning them as the go-to choice for meeting demanding specifications while enhancing operational workflows.

Metal hole openers are increasingly recognized for their versatility, making them indispensable in various industrial applications, particularly in the rubber production sector. The rubber industry heavily relies on precise hole cutting for efficient manufacturing processes, and metal hole openers deliver the reliability and durability needed to withstand rigorous conditions. Their ability to accommodate diverse materials not only enhances productivity but also results in greater precision, a critical factor in maintaining quality standards in rubber production.

Tips for Choosing the Right Metal Hole Opener:

When selecting a metal hole opener, consider the material compatibility and the specific requirements of your application. Opt for tools designed for high-speed cutting to improve efficiency. Additionally, ensure that the opener provides consistent performance across varying temperatures and operational loads to prevent any disruption in the production process.

As industries evolve, the demand for adaptable tools like metal hole openers continues to grow. With automation on the rise, choosing the right equipment can significantly impact overall efficiency and output. Investing in metal hole openers not only meets current industrial needs but also positions businesses to better adapt to future advancements and technologies.