In the realm of woodworking and DIY projects, the right tools can significantly impact the quality of work produced. Among these tools, the Extended Hole Saw stands out as an indispensable asset for professionals and enthusiasts alike. Renowned woodworking expert, James Lancaster, emphasizes its importance by stating, "An Extended Hole Saw provides not just precision, but also the versatility needed to tackle a variety of materials with ease." This insight underscores the utility of this tool in achieving clean, accurate cuts in thicker workpieces that standard hole saws might struggle with.

The extended length of these hole saws allows carpenters and DIYers to drill deeper without compromising on stability, making them ideal for creating larger holes required during complex installations or renovations. Whether setting up plumbing, electrical wiring, or creating vent openings, having an Extended Hole Saw in one’s toolkit ensures you are well-equipped to handle any task. Understanding which models offer the best performance is crucial for anyone serious about woodworking, ensuring both efficiency and high-quality results in every project.

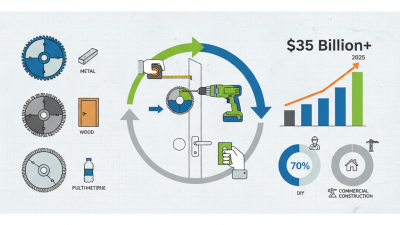

Extended hole saws are essential tools for both professional woodworking and DIY enthusiasts, offering unique features that set them apart from standard hole saws. These tools are designed to reach deeper into materials, allowing users to cut holes that can accommodate various plumbing, electrical, and installation needs. According to industry reports, the demand for extended hole saws has surged by approximately 15% annually, reflecting the growing interest in precision woodworking and advanced home improvement projects.

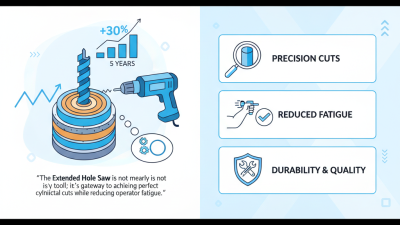

One of the key benefits of extended hole saws is their ability to provide clean and precise cuts through thick materials, including hardwood, softwood, and composites. The extended length of the saws enables users to drill deeper holes without the need for multiple passes, significantly enhancing efficiency and reducing the risk of misalignment. Moreover, their construction materials, often high-speed steel or carbide-tipped, contribute to their durability and long service life. Research indicates that using high-quality extended hole saws can improve cut speed by up to 30%, making them a preferred choice among professionals who value productivity.

In addition to their cutting efficiency, extended hole saws also offer versatility in various applications. Whether it’s for creating holes for fixtures, installing locks, or routing cables, these tools adapt to different tasks with ease. The ergonomic design and compatibility with standard drill chucks further enhance usability, ensuring that both seasoned professionals and DIYers can achieve high-quality results without excessive effort. As the woodworking industry continues to innovate, extended hole saws remain a vital component in the toolkit of anyone serious about crafting and building projects.

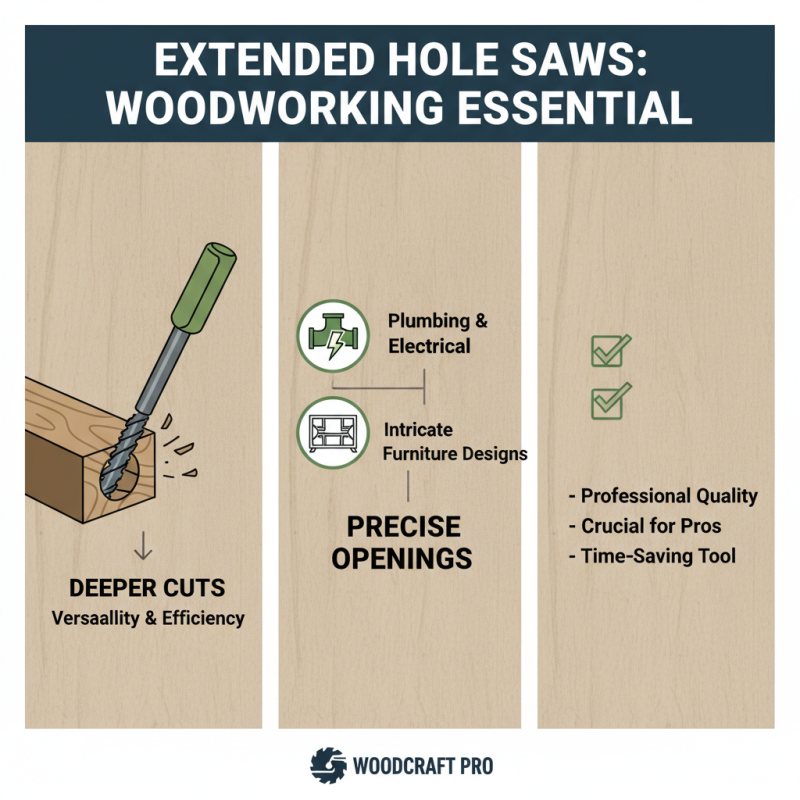

When it comes to woodworking, having the right tools is essential for achieving professional quality results. Extended hole saws are particularly valuable in this arena, as they are designed to cut deeper holes than standard saws, making them ideal for a variety of woodworking projects. Whether it’s for creating precise openings for plumbing or electrical work, or for crafting intricate designs in furniture, these tools provide versatility and efficiency that are crucial for woodworking professionals.

Choosing the right extended hole saw can significantly enhance productivity and precision. Factors to consider include the material of the saw, its cutting depth, and the type of wood being worked on. High-quality extended hole saws are typically made from durable materials that can withstand repeated use while maintaining sharpness. Additionally, the right size and depth are key to ensuring clean and accurate cuts. By selecting the most suitable saw for the job, woodworking professionals can ensure that their projects meet both aesthetic and structural requirements, ultimately elevating the standard of their craftsmanship.

When selecting extended hole saws for woodworking and DIY projects, material compatibility is crucial for achieving optimal cutting performance. The type of material being cut, whether it be softwoods, hardwoods, or engineered wood products, can significantly influence the saw's performance.

For instance, hole saws made from high-speed steel (HSS) are known for their ability to handle tougher materials such as hardwoods, providing clean cuts and enhancing longevity. Conversely, bi-metal hole saws, which combine HSS teeth with a robust backing, are versatile enough to be effective across various materials, including softer woods and composites. This adaptability allows woodworkers and DIY enthusiasts to tackle a range of projects with confidence.

Cutting performance can also be affected by factors such as tooth design and spacing. A hole saw with more teeth will generally produce smoother cuts, making it an excellent choice for detailed work on fine finishes. In contrast, a saw with fewer teeth may cut faster but could sacrifice some edge quality, which is particularly important when working on visible surfaces. Additionally, the thickness of the material being cut should correspond to the type of hole saw used; thicker stock often requires a more robust design. A thorough understanding of these factors ensures that users can make informed decisions and select the appropriate extended hole saws that cater to their specific woodworking needs.

When engaging in DIY projects, choosing the right tools can significantly impact both the efficiency and quality of your work. Extended hole saws are particularly useful for creating larger, cleaner holes in various materials, especially wood. According to a report by the Woodworking Machinery Manufacturers Association, improper tool selection and usage account for nearly 30% of problems faced during woodworking projects. Therefore, understanding how to effectively use extended hole saws can help mitigate these issues and enhance project outcomes.

Essential tips for using extended hole saws focus on preparation and technique. First, it's crucial to select the appropriate pilot bit size, as a well-fitted pilot ensures stability and reduces the chance of binding during operation. Industry data indicates that using a pilot bit that matches the hole saw size can improve cutting efficiency by as much as 40%. Additionally, applying consistent pressure while operating the saw prevents overheating and prolongs the life of the tool. In a survey conducted by the National Wood Product Association, 65% of woodworking professionals reported that maintaining a steady hand and optimal speed significantly reduces the wear on cutting edges and enhances the quality of the cut.

Lastly, safety should never be overlooked. Workers should always use protective eyewear and ensure their workpieces are securely clamped down. Research shows that accidents attributed to improper handling of tools frequently arise from a lack of safety measures, underscoring the importance of these practices in not only achieving effective results but also safeguarding against injury.

When working with extended hole saws, proper maintenance is crucial for ensuring both the longevity of the tools and the safety of the users. One of the key practices is to regularly clean the hole saws after use. This helps to remove wood shavings and debris that can cause rust and affect performance. Using a brush or compressed air can be effective for clearing out the teeth and body of the saw. It's also important to inspect the teeth for any signs of damage or dullness; if they appear worn, sharpening or replacing them is recommended to maintain cutting efficiency.

Safety is paramount when using extended hole saws, and following specific guidelines can minimize risks. Always wear appropriate personal protective equipment, including safety goggles and gloves, to protect against debris and sharp edges. Additionally, ensure that the workpiece is securely clamped to prevent it from moving during the drilling process. Using a drill with a stable power source and applying even pressure can help in achieving clean cuts while reducing the likelihood of kickback. Before starting any project, read the manufacturer's instructions to familiarize yourself with best practices specific to the tool you are using.