In the world of drilling, efficiency and precision are paramount, and the choice of tools can significantly influence the outcome of any project. One of the key advancements in this domain is the High Speed Hole Opener, which has gained popularity for its ability to create clean and precise holes quickly. As industries continue to push the boundaries of their operations, drilling tools must evolve to meet the demands for speed and reliability.

This article explores the 10 best High Speed Hole Openers available in 2023, tailored for professionals seeking to enhance their drilling tasks. From construction to manufacturing, these tools are designed to cut through materials swiftly while ensuring minimal wear and tear. By examining various features, benefits, and application suitability, we aim to provide insights that will help users select the ideal High Speed Hole Opener for their specific needs, thereby optimizing their drilling processes and achieving their operational goals more efficiently.

High-speed hole openers are essential tools in various drilling applications, designed to increase efficiency and reduce project time. These tools come into play when creating larger diameter holes in hard and abrasive materials like concrete, metal, or stone. Engineered for durability and precision, high-speed hole openers utilize advanced materials and cutting technologies to optimize performance, allowing operators to drill through tough surfaces with ease and speed.

The demand for these tools has surged in industries such as construction, mining, and oil exploration, where time and accuracy are critical.

The versatility of high-speed hole openers extends to numerous applications beyond simple drilling tasks. They are commonly used in the installation of plumbing and electrical systems, making them invaluable for both residential and commercial projects. Additionally, these tools have been adopted in the aerospace and automotive sectors for manufacturing and assembly tasks that require precise hole creation.

As advancements in technology continue to shape the drilling industry, high-speed hole openers remain a vital component in improving operational efficiency and enhancing productivity across a variety of fields.

When selecting a high speed hole opener, several factors must be considered to ensure optimal performance and efficiency. The drill bit material is crucial—carbide-tipped options are often preferred for their durability and strength, making them ideal for high-speed applications. According to industry reports, drill bits made from high-speed steel (HSS) can operate at speeds exceeding 300 RPM, while carbide alternatives can withstand higher temperatures, leading to longer tool life and reduced downtime. Moreover, the geometry of the hole opener plays a significant role; a refined cutting edge can enhance precision and decrease resistance during drilling, thus promoting faster and more efficient operations.

Another key consideration is the hole opener size and design. Choosing the right diameter is vital for matching the drilling application requirements. Data from a recent market analysis indicates that high speed drilling can increase productivity by up to 50% when using the appropriate hole opener size for the task. Additionally, the design of the hole opener, specifically the spindle and cutting pattern, needs to align with the material being drilled. For example, for softer materials, a wider cutting surface might speed up progress, while for harder substrates, a more narrow design could provide the necessary control and depth precision. These factors collectively enhance drilling efficiency, resulting in better output for construction and industrial projects in 2023.

This chart compares the drilling speeds of the top 10 high speed hole openers for efficient drilling in 2023. Higher values indicate better performance.

When it comes to drilling efficiency, choosing the right high-speed hole opener is vital for achieving optimal results across various applications. According to a report from the IADC, the demand for high-performance drilling tools has surged by 25% in the past five years, driven by advancements in technology and increasing industrial activities. High-speed hole openers are designed to handle a wide range of materials, making them essential for construction, mining, and oil & gas sectors. These tools not only enhance drilling speed but also minimize wear and tear, ensuring cost-effective operations.

The versatility of high-speed hole openers allows them to be utilized in both soft and hard substrates. Recent studies have shown that using the right type of hole opener can increase drilling speed by up to 40% compared to standard tools. This efficiency is critical, especially in large-scale projects where time and budget constraints are paramount.

As industries increasingly turn to automation and modern drilling techniques, selecting a high-speed hole opener that meets specific drilling needs can greatly impact overall productivity and success. With an array of options available, professionals must consider factors such as material compatibility, diameter size, and heat resistance to ensure they choose the most effective tool for the job.

In the realm of drilling technology, high-speed hole openers have become indispensable tools for enhancing operational efficiency. According to a report from the International Association of Drilling Contractors, the demand for high-performance drilling tools has surged by 25% over the past three years, largely due to increased drilling activities in sectors such as construction, mining, and oil and gas extraction. The capability of a hole opener to maintain speed without compromising on precision is critical, as the average cost of rig downtime is estimated at $25,000 per day.

A comparative analysis of performance metrics among different high-speed hole openers reveals significant variances in penetration rates, durability, and temperature resilience. A study published in the Journal of Petroleum Technology indicates that top-performing models can achieve penetration rates exceeding 300 feet per hour under optimal conditions, showcasing a distinct advantage over conventional openers. Additionally, materials engineered for enhanced thermal resistance and wear protection significantly reduce maintenance intervals, making them a cost-effective choice in high-stress environments. These advancements underscore the importance of selecting the right hole opener based on specific drilling conditions and objectives to maximize efficiency and minimize operational costs.

| Model | Diameter Range (inches) | Material Type | Max RPM | Weight (lbs) | Performance Rating (1-10) |

|---|---|---|---|---|---|

| Model A | 1" - 4" | High-Speed Steel | 3000 | 5 | 9 |

| Model B | 2" - 6" | Carbide | 2500 | 6 | 8 |

| Model C | 1.5" - 5" | Titanium | 2800 | 4.5 | 9 |

| Model D | 2" - 8" | Cobalt | 2400 | 7 | 7 |

| Model E | 1" - 3.5" | Bimetal | 3200 | 3 | 10 |

| Model F | 2" - 10" | High-Speed Steel | 2200 | 9 | 8 |

| Model G | 1" - 4.5" | Titanium | 2600 | 4 | 9 |

| Model H | 2" - 7" | Carbide | 2900 | 8 | 8 |

| Model I | 1.5" - 6" | Cobalt | 2300 | 5.5 | 7 |

| Model J | 2" - 5" | Bimetal | 3000 | 4 | 9 |

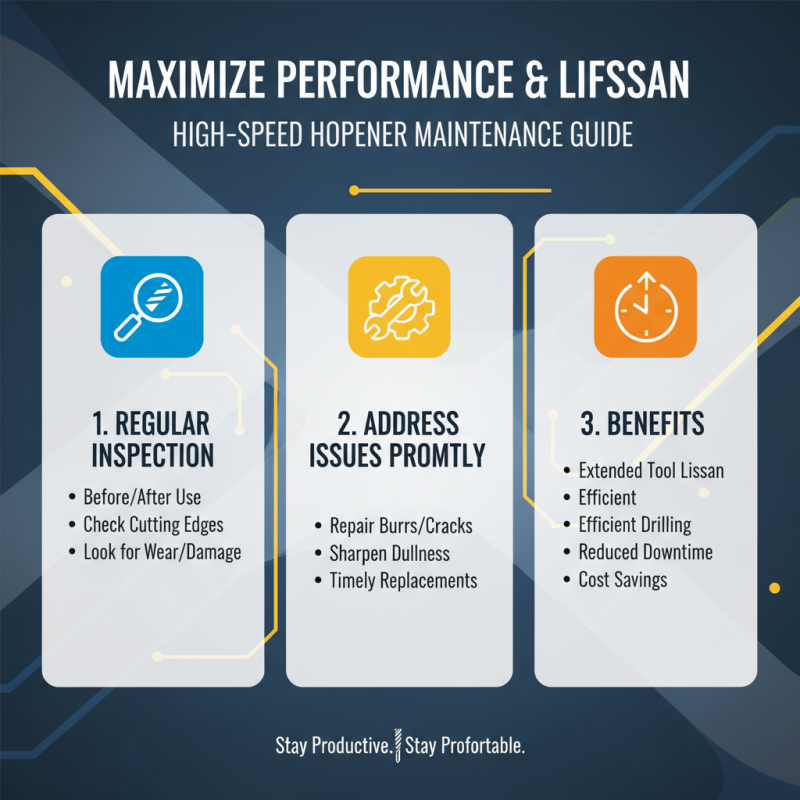

Proper maintenance of high-speed hole openers is crucial for extending their lifespan and ensuring efficient drilling performance. Regular inspection is the first step in this maintenance regimen. Before and after use, operators should check for signs of wear or damage to the cutting edges and body of the hole opener. Any burrs, cracks, or dullness should be addressed immediately, allowing for timely repairs or replacements that can prevent costly downtime during projects.

Additionally, keeping the hole openers clean is vital. Debris and drilling mud can accumulate on the tools, affecting their performance and efficiency. A thorough cleaning after each use will help to prevent material buildup that can lead to corrosion or other damage. Lubrication also plays an essential role; applying the appropriate lubricant can reduce friction and wear on the moving parts, thus improving overall functionality. By adopting these simple maintenance practices, operators can ensure that their high-speed hole openers remain in optimal condition, leading to more productive and efficient drilling operations.