The Bi Metal Hole Saw is a powerful tool in cutting applications. Experts agree on its effectiveness. James Miller, a seasoned contractor, once stated, "The right hole saw can change your project." This highlights the importance of understanding their use.

Using a Bi Metal Hole Saw doesn't come without challenges. Choosing the right size can be tricky. The blade's thickness matters too. Both impact the cutting process significantly. New users often struggle to maintain proper pressure, which is crucial for smooth cuts.

Practicing with a Bi Metal Hole Saw is essential. Many users report common mistakes, like incorrect speed settings. Taking time to learn will improve results. Prepare your workspace properly. The clearer it is, the easier the project becomes. Mastering these techniques can lead to impressive achievements.

Bi-metal hole saws are popular for their durability and versatility. Made from high-speed steel and a body of more resilient metal, they’re perfect for cutting through various materials like wood, metal, and plastic. The combination of these materials allows for smooth cuts and longevity, making them a preferred choice for many DIY enthusiasts and professionals alike.

When using bi-metal hole saws, there are some valuable tips to consider. Ensure the hole saw is appropriate for the material you are cutting. Many make the mistake of using the wrong type, which can lead to dull blades quickly. Maintain a steady speed while cutting. Too much pressure can damage the saw and ruin your materials. Remember, patience is key.

Another crucial point is to keep the saw clean. Clogged teeth can cause overheating. Take a moment to clear any debris during prolonged use. Many forget this step and end up with poor results. While bi-metal hole saws are effective, neglecting these tips can lead to frustration and wasted time.

Choosing the right bi-metal hole saw is crucial for project success. The right choice can optimize performance, save time, and reduce costs. According to industry data, improper selection leads to a 30% increase in operational costs due to wasted materials and extended labor. Knowledge of sizes and tooth configurations prevents these pitfalls.

Consider the material being drilled. For instance, thin metals require different saws compared to hardwood or plastic. Bi-metal hole saws with variable pitch teeth aid in cutting through diverse materials, enhancing efficiency. Many professionals overlook the importance of RPM settings. Using the correct speed can minimize tool wear and maximize the lifespan of the saw.

Additionally, many users ignore the necessity of using cutting fluid. This simple technique can prolong the life of the hole saw. Studies indicate that using coolant reduces friction by up to 50%. However, selecting the right coolant is essential. Some fluids can damage specific materials. Understanding these nuances can make a significant difference in project outcomes.

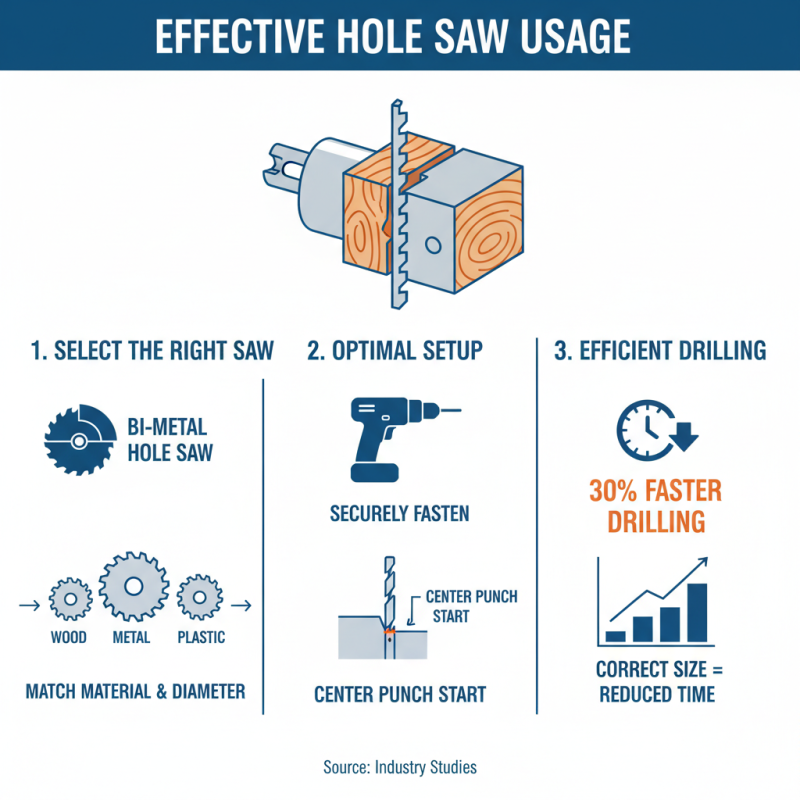

When preparing for effective hole saw usage, ensuring proper setup is crucial. Start by selecting the right bi-metal hole saw for your project. According to industry studies, using the appropriate size can reduce drilling time by up to 30%. It's essential to match the hole saw diameter to the material thickness for optimal results.

Before drilling, mark the exact location for your hole. A reliable method is to use a center punch for precise placement. It helps stabilize the drill bit during the initial cut. Many users overlook this step, leading to misaligned holes and wasted materials. Given that nearly 20% of projects face delays due to rework, this simple tip can save time and resources.

Check your drill’s speed settings. The recommended RPM varies based on the material type. For metal, a slower speed helps prevent overheating. Research indicates that 60% of all drilling issues stem from improper speed settings. Be mindful of the pressure applied during drilling as well. Too much force can cause the saw to bind or dull quickly. Balancing speed and pressure is key for efficient operation.

Drilling with bi-metal hole saws can be straightforward. Start by selecting the right size for your project. Measure twice to ensure accuracy. For wood, select a larger hole saw. For metal, a more precise size is key.

Before you start, always wear safety gear. Safety goggles and gloves can protect you well. It's easy to forget this step. Secure the material firmly. Wobbly items lead to uneven holes or even accidents.

Tips: Keep the hole saw cool. Too much heat can dull the teeth quickly. Use a lubricant for metal surfaces. It helps the saw cut smoothly. Also, check the teeth regularly. If they seem worn out, replace them promptly. This can save time and effort later.

Be patient while drilling. Rushing often leads to mistakes. Take breaks if needed. Sometimes, finesse beats speed. Drilling a clean hole takes practice and concentration. Don’t hesitate to experiment. Learn from any missteps along the way.

| Tip | Description | Application |

|---|---|---|

| Choosing the Right Size | Select a hole saw that matches the diameter required for your project. | Woodworking, plumbing installations |

| Using Cutting Fluid | Apply cutting fluid to prevent overheating and improve cutting efficiency. | Metal, fiberglass, plastic |

| Drilling Speed | Use lower speeds for harder materials to avoid damage and tooth breakage. | Metal and dense hardwoods |

| Backer Board | Use a backer board to prevent tear-out on the exit side of the material. | Plywood, composite materials |

| Proper Pressure | Apply steady, consistent pressure while drilling to maintain a clean cut. | All applications |

Proper maintenance of bi-metal hole saws can greatly enhance their lifespan. After each use, cleaning is essential. Debris and metal shavings can accumulate and dull the cutting edges. A simple brush or compressed air can effectively remove these particles. Always check the teeth for wear or damage. Addressing issues early can prevent more extensive repairs.

Storage plays a key role in caring for hole saws. Ensure they are kept in a dry place to avoid rust. A container or designated tool rack can minimize the risk of accidental damage. It's also beneficial to keep them organized, making it easier to find the right size when needed. This prevents unnecessary wear that may come from searching through disorganized tools.

Regularly lubricating the saw can enhance performance. A few drops of oil on the bit reduces friction. It’s a small step, but it’ll make a big difference. Using the right cutting speed is another vital aspect. Too fast and you risk overheating; too slow can result in binding. Finding a balance can take practice and patience.