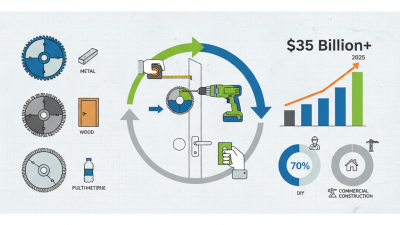

In the realm of construction and DIY projects, a Carbon Hole Saw is an essential tool. This specialized saw allows for precise cuts in various materials. According to a recent report by IBISWorld, the tool manufacturing industry is projected to grow by 4% annually. Such growth underscores the importance of understanding tools like the Carbon Hole Saw.

This saw features a unique design that enables it to cut through tough materials while minimizing waste. With advancements in technology, these saws now offer greater durability and efficiency. Utilizing a Carbon Hole Saw can save time and improve the quality of your work. However, not every user maximizes its potential. Some may struggle with maintaining the proper speed or pressure, leading to less-than-ideal outcomes.

Employing a Carbon Hole Saw correctly requires practice and attention to detail. While many users enjoy its benefits, some find it challenging. This gap in expertise can result in uneven or incomplete cuts. Understanding how to effectively use this tool is crucial for achieving the desired results.

A carbon hole saw is a specialized tool designed for creating clean, uniform holes in various materials. This tool is ideal for professionals and DIY enthusiasts alike, as it accommodates a range of applications, including woodworking, metalworking, and electrical work. According to industry reports, more than 30% of construction workers now prefer carbon hole saws for their efficiency and durability compared to traditional methods.

This type of saw features a hollow, cylindrical design with sharp teeth that easily cut through materials. Users often appreciate its ability to penetrate different surfaces, such as drywall, tiles, and even thin metals. With proper use, carbon hole saws can generate minimal debris and reduce the risk of damage to surrounding areas. However, mistakes happen. Some users struggle with alignment or apply excessive pressure, leading to uneven holes.

Tips: Always measure twice before cutting. Ensure the surface is stable to avoid movement. Use slow and steady pressure for better results. Remember, patience is key. Drilling too quickly may result in errors.

Overall, understanding the versatility and proper handling of carbon hole saws can enhance project outcomes. With the right preparation and technique, this tool can be a valuable addition to any toolbox. Users must also be aware of their limits. Overuse might lead to blunted edges, making future cuts less effective.

Carbon hole saws are essential tools in various industries. They are primarily used for cutting precise holes in various materials, including wood, plastic, and metal. A vital feature of these saws is their superior durability. Reports indicate that carbon hole saws can last up to three times longer than standard steel saws. This durability reduces replacement costs over time.

The design of a carbon hole saw often includes a bi-metal construction. This provides enhanced toughness and wear resistance, suitable for tough jobs. Additionally, the teeth configuration allows for faster cutting. Many users note that the improved cutting speed can save significant time on projects. However, it's important to note that even high-quality hole saws do have limitations. For instance, they may struggle with certain dense materials, leading to a need for multiple passes.

Another critical aspect is the size variety available in carbon hole saws. They come in various diameters to accommodate different tasks. This versatility makes them a favorite among contractors and DIY enthusiasts alike. Yet, users must be mindful of the specific material they are cutting. Some reports highlight issues with overheating when cutting thicker materials. Therefore, proper technique and cooling strategies are essential for achieving the best results.

| Feature | Description | Typical Use Cases |

|---|---|---|

| Material Type | High-carbon steel | Wood and soft metals |

| Diameter Range | 0.5 inches to 6 inches | Varied applications, from electrical wiring to plumbing |

| Cutting Depth | Up to 2 inches | Sheet material and thick boards |

| Cutting Speed | High speed, smooth finish | Fast installation and construction tasks |

| Compatibility | Fits standard drill chucks | Cordless and corded drills |

| Maintenance | Requires periodic sharpening | Long-term use benefits |

Carbon hole saws are versatile tools used in various applications. They excel at cutting through materials like wood, metal, and plastics. Their robust design allows for clean and precise holes. For instance, when cutting wood, these saws can create smooth edges without splintering. This is crucial for projects where aesthetics matter.

In metalwork, carbon hole saws are beneficial for creating holes in pipes and sheet metal. They maintain sharpness longer than standard saws, leading to effective cutting. Always ensure you use the correct speed and pressure. Too much pressure can damage the material.

Tips: Make sure to keep the saw lubricated. This will extend its life. When working with hard materials, take breaks. This reduces overheating. Remember to wear safety gear, as flying debris can cause injuries. Missteps can lead to broken bits and wasted time. It’s important to review your technique regularly to avoid mistakes.

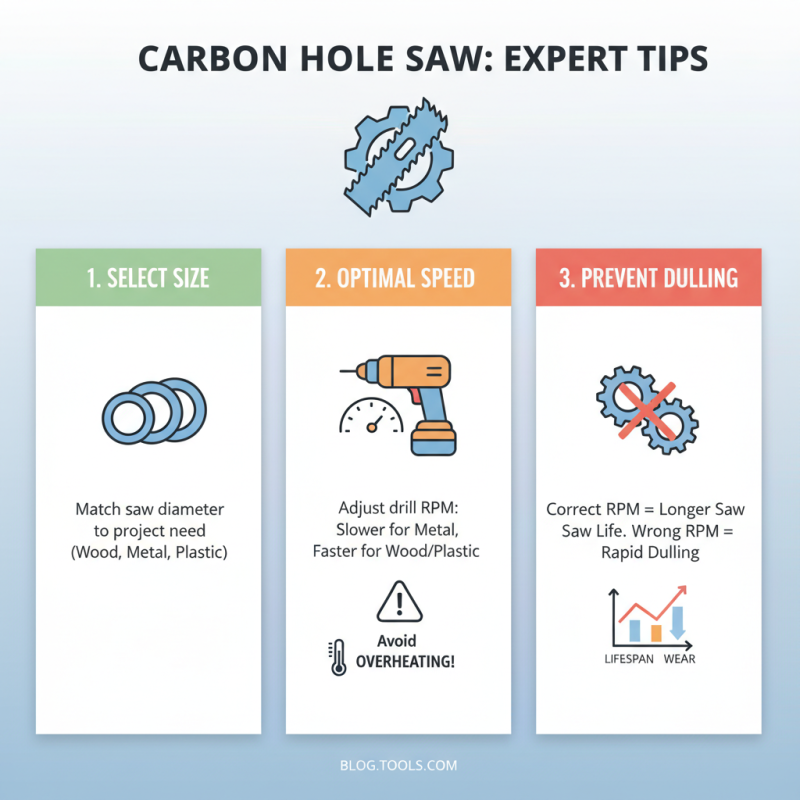

Using a carbon hole saw can be straightforward, but it requires attention to detail. Start by selecting the right size of the hole saw for your project. A typical carbon hole saw is designed for cutting through various materials such as wood, metal, and plastic. According to industry reports, it’s essential to use the correct speed settings on your drill to avoid overheating. A common error is using the wrong RPM, which can lead to a rapid dulling of the saw.

Before starting, mark the center point on your work surface using a pencil. It’s crucial to ensure the pilot bit fits properly to guide the hole saw. A misalignment here can cause uneven cuts. Ensure your workspace is stable. If your material shifts during cutting, it can ruin the entire project. In fact, over 30% of professionals report that misalignment leads to wasted materials and time.

As you cut, apply steady pressure. It’s tempting to force the saw through, but this can create jagged edges. Patience is key. Periodically withdraw the saw to clear out debris. Ignoring this tip can lead to clogging and overheating. Finally, clean the edges of your hole carefully. Jagged edges may not be suitable for the intended function. Being detail-oriented will improve overall results.

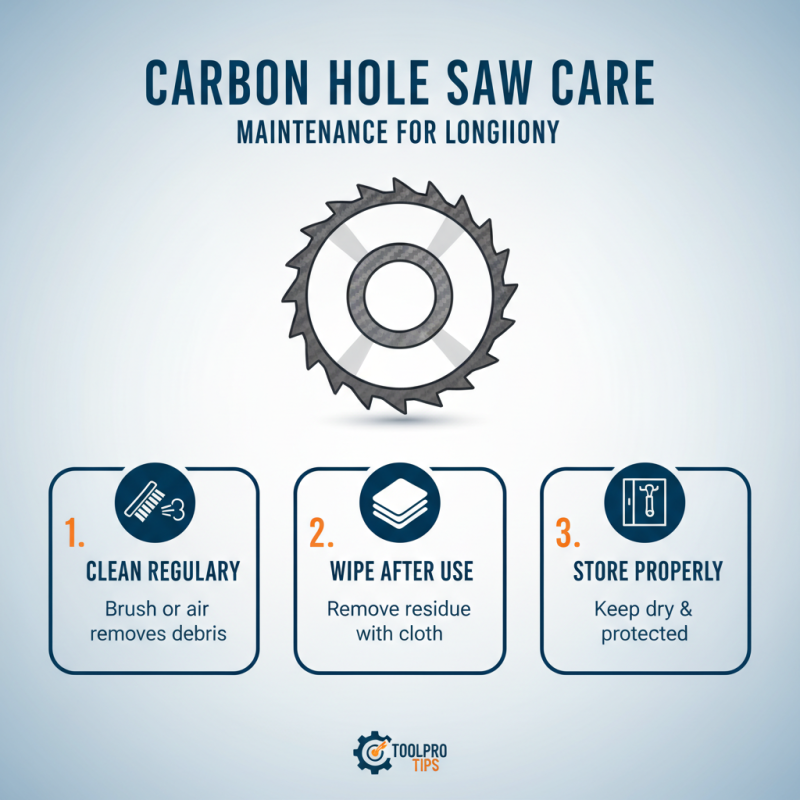

Carbon hole saws are essential tools for creating precise holes in various materials. Proper maintenance is crucial for longevity and performance. Regular cleaning can prevent build-up of debris. A brush or compressed air works well for this task. After use, always wipe the saw with a cloth to remove any residue.

Storage matters, too. Place the saws in a protective case to avoid damage. Keep them away from moisture. Excessive dampness can cause rust. A study by the Tool Manufacturers Association highlighted that regular maintenance can extend the tool’s lifespan by over 30%.

Tip: Use cooling lubricants during operation. This can significantly reduce wear. Also, check the saw for any signs of wear or damage before each use. Inspect teeth for clarity; dull teeth make cutting harder. Regularly reviewing your tools can prevent frustration and unexpected costs. A little attention goes a long way.