When embarking on a drilling project, choosing the right tool is essential. A High Speed Hole Opener is a key component in achieving precision and efficiency. The market is filled with various options, each designed for specific tasks. It's vital to know which features best suit your needs.

Understanding the specifications of a High Speed Hole Opener can seem overwhelming. Factors like size, material, and speed play significant roles. Each project requires a unique approach and tool selection. A mismatch can lead to frustration and wasted resources. Reflecting on past experiences can guide your choice.

It's important to evaluate not only performance but also durability. A good Hole Opener should withstand the rigors of your specific project. Balancing cost and quality is another challenge. Sometimes, the most expensive option isn’t the best fit. Consider both the short-term and long-term implications of your choice. A thoughtful decision can make all the difference in your project's success.

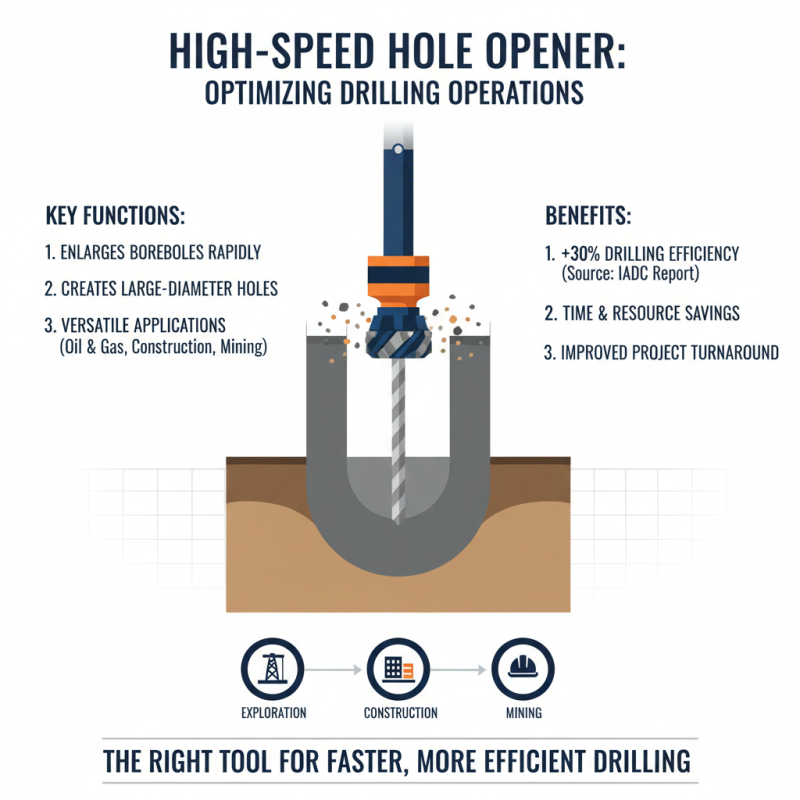

Understanding the function of a high-speed hole opener is crucial for effective drilling operations. These tools are designed to create large-diameter holes quickly. They are commonly used in various applications such as oil and gas exploration, construction, and even mining. According to a report by the International Association of Drilling Contractors, the right hole opener can increase drilling efficiency by over 30%. This improvement can save both time and resources.

When selecting a high-speed hole opener, consider the material being drilled. Different materials require specific cutting structures. For instance, rock drilling may need carbide inserts for durability. Not all openers perform equally, and mismatches can lead to subpar results. Keeping an eye on wear and tear is essential. This can help in maintaining optimal performance during the drilling process.

Tips: Always assess the diameter required for your project. A mismatch can waste time and resources. Monitor the condition of your hole opener regularly. If you notice excessive wear, it may be time for a replacement. Ideal drilling conditions are not always guaranteed. Be ready to adjust your approach based on material and environmental factors.

Choosing the right high-speed hole opener is crucial for the success of your project. There are several key factors to consider. The size of the hole opener must match your requirements. Different projects require various hole sizes. Assess the material you will be working with as well. Certain openers perform better with specific materials.

Material quality matters, too. Durable materials can handle tough conditions. Look for models designed for longevity. Check the specifications for the type of cutting edge. It significantly influences performance.

Tip: Always read user reviews. They provide insights into real-world applications. Testing an opener before purchase can save time and money.

Another factor is the weight of the opener. Heavier options may require more effort to handle. Consider whether you can manage it comfortably. Additionally, think about the maintenance requirements of the hole opener. Some options need regular upkeep, which can be demanding.

Tip: Keep an eye on the brand's support services. A responsive customer service team can assist with any issues. Investing time in research pays off in the long run. Stay aware of your project's unique needs. Each project is different and may present unexpected challenges.

| Feature | Description | Importance |

|---|---|---|

| Material | Commonly made from high-speed steel or carbide. | Determines durability and effectiveness. |

| Size | Available in various diameters for different hole sizes. | Crucial for meeting project specifications. |

| Drilling Speed | Rated by RPM; affects efficiency and hole quality. | Higher speeds can improve productivity. |

| Cooling Method | Involves the use of water or air to reduce heat. | Prevents tool wear and prolongs lifespan. |

| Compatibility | Must be compatible with the drill and equipment. | Ensures efficient and safe operation. |

| Cost | Price can vary widely based on features and materials. | Affects budget and project feasibility. |

| Brand Reputation | Based on user reviews and industry feedback. | Can indicate reliability and performance. |

High speed hole openers come in various types, each serving distinct purposes in different applications. One common type is the auger bit. Auger bits drill quickly and effectively, ideal for soft materials like wood and plastic. They are designed to remove waste efficiently but may struggle with harder surfaces, leading to blunt edges that require regular sharpening.

Another popular option is the carbide-tipped hole saw. These tools excel in cutting through thicker materials such as metal and masonry. According to industry research, carbide-tipped tools can last up to ten times longer than standard steel options when used correctly. However, their operating cost can be high if not handled with care. Over time, improper technique may lead to inefficiencies and a need for costly replacements.

Dotting the landscape of high-speed drilling, we also have twist drills. They are versatile and can be used on a variety of materials but often lack speed in tougher applications. A poorly chosen drill can increase project delays. Users should evaluate specific needs and consider factors like material type and desired hole size before making a decision.

When selecting a high-speed hole opener, consider the materials used in its construction. Common materials include steel, carbide, and cobalt. Each offers unique benefits. Steel is often durable but may wear faster. Carbide tools shine in tough applications, providing longevity and precision. Cobalt is a robust option, particularly for drilling into hard surfaces. The right material affects the performance of your project significantly.

Tips: Always check the specifications for the hardness ratings. This insight can guide you in matching the hole opener to your project needs. Choose a tool that fits your specific tasks.

Durability is another crucial factor. Look for openers that boast wear-resistant coatings. This feature prolongs the tool's lifespan. Even with the best choices, some tools fail to meet expectations. Regular maintenance and inspection can help. Evaluate if the performance drops with usage. This can inform future purchases.

Tips: Testing a few options on scrap material may provide clarity. Don’t hesitate to swap models if one doesn’t perform as expected. Performance and reliability are vital. Aim for tools that adapt to various tasks, enhancing your overall efficiency.

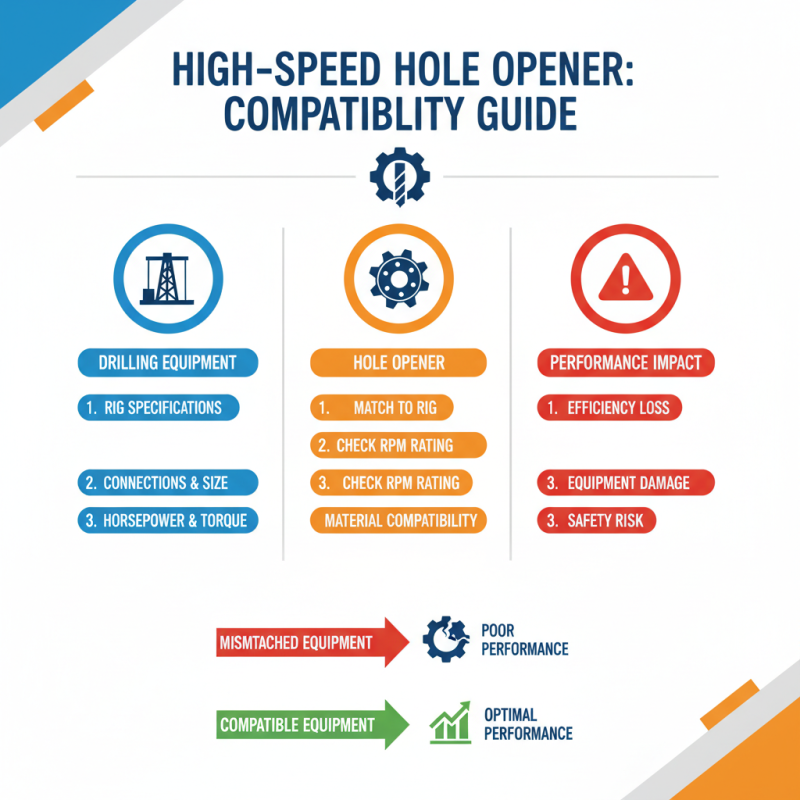

When choosing a high-speed hole opener, compatibility with your existing drilling equipment is key. Different drilling rigs have various specifications, which can affect performance. Assessing the connections and size of your current tools is essential. Consider factors like horsepower and torque output. Mismatched equipment can lead to inefficiencies or even damage.

Take time to measure the dimensions of your current setups. Compare these measurements against the specifications of the hole opener. Some users find discrepancies they initially overlooked. This can lead to frustration on site. Small inconsistencies can mean the difference between a smooth operation and potential downtime. Don't forget to consider the materials used in the hole opener. Harder materials can withstand more wear but may affect compatibility with softer equipment.

It’s also worth reviewing user feedback on performance with similar setups. First-hand experiences can shine a light on potential issues. Sometimes, enthusiasts share unexpected concerns that aren’t listed in manuals. Investing time in this step may save you significant headaches later. A thoughtful approach to compatibility ensures your project proceeds smoothly and efficiently.