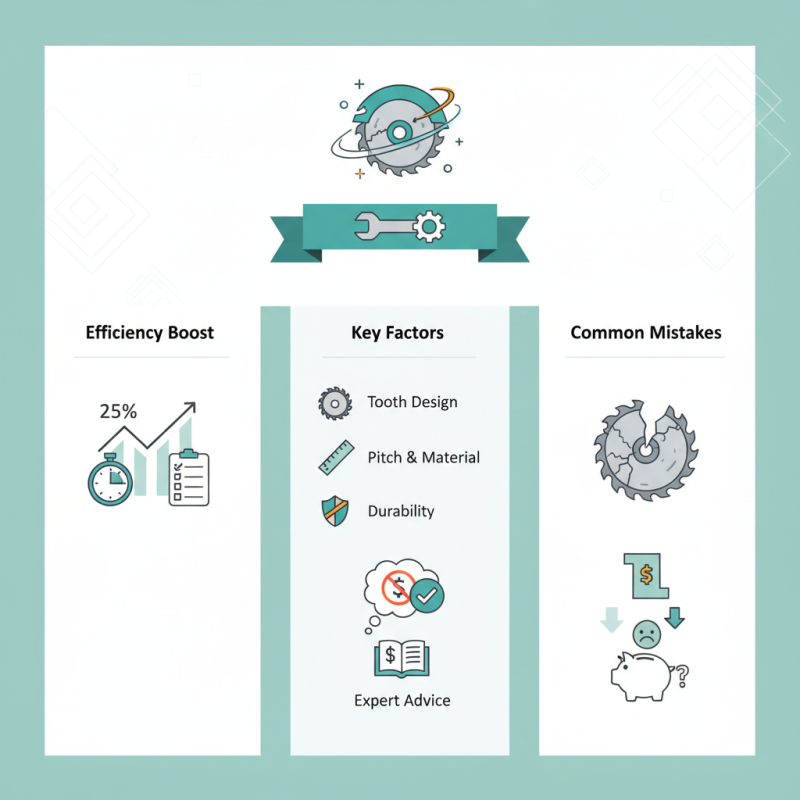

Choosing the right Bi Metal Hole Saw is crucial for project success. Industry reports indicate that selecting the proper hole saw can improve efficiency by up to 25%. This makes understanding specifications essential for any contractor or DIY enthusiast.

Expert John Smith, a leader in the cutting tools industry, emphasizes, “A high-quality Bi Metal Hole Saw can significantly reduce wear and tear.” Durable teeth and the ability to cut through various materials make these tools indispensable. However, many users still struggle to find the best options on the market.

With a plethora of choices, factors such as tooth design, pitch, and material must not be overlooked. Many Mistakes arise from choosing based on price alone. Users often find themselves dealing with premature wear and disappointing results. Seeking expert advice can make a difference in tool selection. Understanding the finer details can ensure a smoother project.

Bi-metal hole saws are essential tools for various cutting tasks. They combine high-speed steel and carbon steel. This combination offers durability and flexibility. They are widely used in electrical work, plumbing, and woodworking. Understanding their applications helps in choosing the right one for your project.

These saws excel at cutting through tough materials, like metal and wood. They reduce friction during cutting, which prolongs their lifespan. However, they might not be suitable for very hard metals. You'll notice that navigating different thicknesses can be challenging. Sometimes, they can bind or overheat if not used correctly. It's important to slow down when cutting hard materials.

When selecting a bi-metal hole saw, consider your project requirements. Assess the material you’ll be cutting. This decision impacts the size and type of the saw. Larger diameters are useful for bigger holes but can be harder to handle. Likewise, make sure you check the compatibility with your drill. Choosing the wrong size can lead to frustrating results and wasted materials.

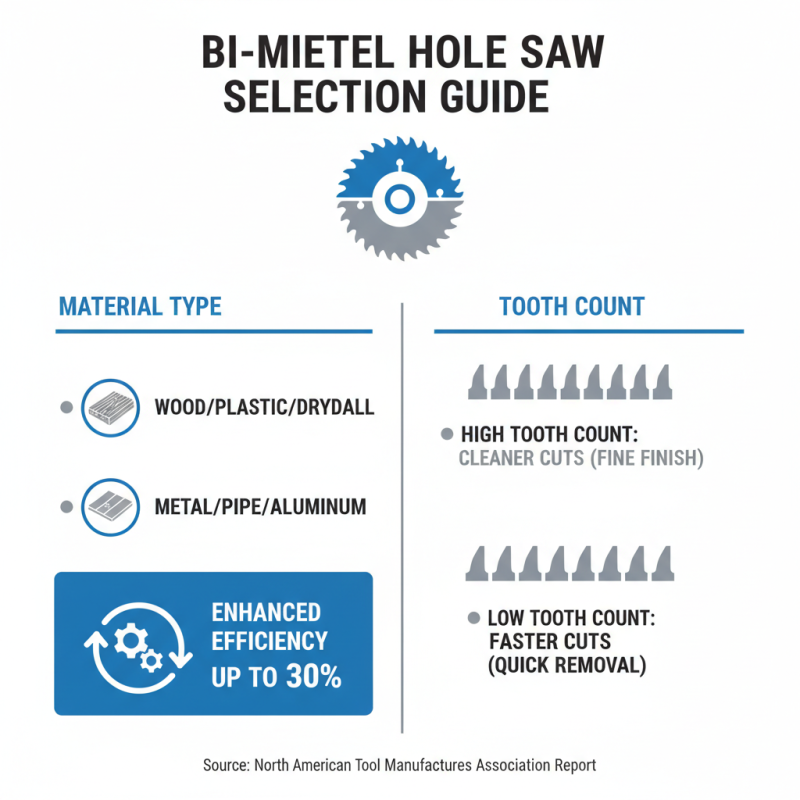

When selecting a bi-metal hole saw, consider the material you will be working with. Bi-metal hole saws excel in cutting through various materials, from wood to metal. According to a report by the North American Tool Manufacturers Association, the right choice can enhance cutting efficiency by up to 30%. A saw with higher tooth count provides cleaner cuts, while a lower tooth count can increase speed.

Another factor is the size of the hole saw. Choose sizes that meet your project requirements. Using an incorrect size may result in inefficiencies or additional work. The diameter affects speed and material removal rate. A smaller diameter can be quite effective for detail work but may take longer on larger projects.

Durability is crucial. Check the thickness of the walls and the material composition. Advanced bi-metal saws provide longer life, especially when cutting harder materials. However, they may come at a premium cost. Balancing quality and budget can be challenging. Poor choices often lead to premature wear and increased costs over time. Reflect on these factors carefully to ensure you select the best tool for your needs.

When you embark on a project requiring a bi-metal hole saw, size matters greatly. Different sizes serve various purposes. A smaller diameter saw, for example, is ideal for delicate tasks, like creating holes for wiring or plumbing fixtures. It allows for precision. Larger diameters work well for tougher materials, such as plywood or hardwood. They can be a bit clunky if you're not careful.

Types of bi-metal hole saws also vary. Some are designed for cutting metal, while others excel at wood. The tooth design plays a crucial role here. Sharp teeth can make cutting effortless, but they wear down faster. It's important to choose wisely and consider your project's demands. You may encounter issues if you select the wrong type. Always assess the material you’ll be cutting.

Material quality is another factor to reflect on. Higher quality saws tend to last longer, but they come with a higher price tag. Is the investment worth it for a one-time project? Sometimes, trial and error is necessary. You might start with a more affordable option. Just remember, your choice of size and type will directly affect your results.

When selecting a bi-metal hole saw, ensuring optimal performance is crucial. Proper maintenance significantly extends the tool's lifespan. According to industry reports, regular cleaning can enhance cutting efficiency by up to 30%. After each use, removing debris helps maintain sharpness. It’s essential to inspect the teeth for wear. A chipped tooth can lead to uneven cuts and increased friction, which compromises both speed and accuracy.

Choosing the right speed for your material is vital. For instance, softer materials like wood require a higher RPM, while harder metals perform better with slower speeds. Data suggests that operating at the optimal RPM can reduce heat buildup by 40%, preventing premature wear. Additionally, using cutting oil can enhance the longevity of the saw. Only a few drops can improve cutting performance and prolong the life of the saw by minimizing friction.

Don't overlook the importance of steady pressure. Too much force can lead to breakage, while too little can cause slow progress. Striking a balance is necessary. Incorrect pressure can result in a wasted effort and lost time. Always consider the nature of your project. Many users fail to adapt their techniques based on material, which can lead to frustration and inefficiency.

When using bi-metal hole saws, safety and efficiency are paramount. Many professionals emphasize the need for proper gear. Wearing safety glasses protects your eyes from metal shavings. Ear protection is also recommended, especially for metal drilling, as the noise can be loud. The average noise level during operation can reach 90 decibels, which is harmful over time.

Tip: Always secure your workpiece. An unstable surface can cause the hole saw to bind and kick back. This not only ruins your project but can lead to injuries. A clamped workpiece allows for cleaner cuts and better control.

Another best practice involves selecting the right speed. According to industry reports, a slow speed often yields better results in harder materials, reducing wear on the tool. For softer materials, a higher speed may suffice. Many users fail to adjust the speed based on the material type, resulting in unnecessary tool wear.

Tip: Regularly inspect your hole saw for damage. Even minor dents can affect cutting quality and safety. A little care goes a long way in extending tool life. Users often overlook this, leading to inefficiencies in their projects.

| Feature | Description | Best For |

|---|---|---|

| Material Composition | Bi-metal construction with high-speed steel teeth. | Wood, metal, and plastic applications. |

| Tooth Design | Variable pitch teeth for faster cutting and smoother holes. | General-purpose drilling tasks. |

| Size Variety | Available sizes range from 3/4" to 6". | Different size requirements of projects. |

| Cutting Depth | Typically around 1.5" to 2". | Thicker materials. |

| Compatibility | Fits most standard drill chucks. | Various drilling setups. |

| Cooling Methods | Use of lubrication for prolonged life. | Heavy-duty drilling. |