In the ever-evolving landscape of construction and DIY projects, the need for precision and efficiency has never been more critical. Among the essential tools that have transformed how we approach various tasks is the Door Hole Saw, a device that combines functionality with ease of use. As projects demand greater accuracy and speed, the traditional methods of drilling and cutting are being redefined, showcasing innovative solutions tailored for the modern craftsman.

This blog will explore the future of Door Hole Saw applications, focusing on cutting-edge techniques and tools that not only enhance performance but also streamline the workflow in your projects. Whether you're a seasoned professional or a DIY enthusiast, understanding these efficient solutions will empower you to achieve exceptional results while maintaining a high standard of workmanship. Join us as we delve into the advancements that are shaping the future of Door Hole Saw usage in the industry.

When embarking on any project involving door installation, selecting the right door hole saw is crucial to achieving a clean and precise cut. The right saw will not only save you time but also ensure that the door fits perfectly without unnecessary adjustments. With a multitude of options available, it's essential to consider factors such as the material of the door, the size of the hole needed, and the overall quality of the saw itself.

**Tips:** Prioritize saws made from high-speed steel or carbide-tipped for durability and longevity. Also, ensure the saw’s teeth are designed for the material you’re cutting; for instance, a saw specifically designed for wood will not perform as well on metal.

Investing time in research can significantly improve your project outcomes. Look for reviews and tested performance for various saws, similar to how drill bits have been evaluated in recent articles. Choosing the ideal door hole saw can make the difference between a straightforward installation and a frustrating experience filled with errors.

**Tips:** Before starting, mark your cutting area clearly to avoid mistakes, and consider using a pilot bit to guide the saw, especially if precision is paramount for your project. Having the right tool not only enhances your efficiency but also elevates the quality of your work.

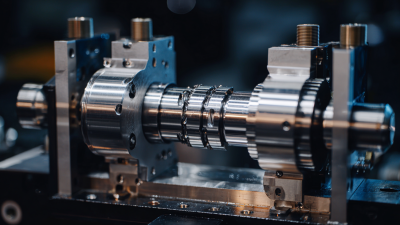

When selecting a door hole saw for your projects, there are several key features to consider to ensure efficiency and effectiveness. First and foremost, the material of the hole saw is crucial. Look for high-quality steel options that provide durability and longevity, allowing for clean cuts through various door materials. Additionally, the design of the teeth is important; teeth with optimized geometry can enhance cutting speed and reduce friction, thus prolonging the lifespan of the tool.

Another feature to keep in mind is compatibility with your chosen drill. Choosing a hole saw that fits well with your drill will ensure that you can achieve the necessary power for your needs. Modern drills are engineered to deliver maximum torque and battery efficiency, which is essential when tackling many hole saw applications. A drill with a reliable battery life allows you to work longer without interruptions, contributing to a smoother workflow. By carefully considering these aspects, you can select a door hole saw that not only meets your expectations but also elevates your overall project efficiency.

| Feature | Description | Importance Level |

|---|---|---|

| Material | High-speed steel (HSS), Bi-metal construction for durability and heat resistance | High |

| Size Options | Variety of diameters to fit different door hole requirements | Medium |

| Teeth Configuration | Number of teeth affects cutting speed and finish quality | High |

| Cutting Depth | Depth should match door thickness for best performance | High |

| Pilot Bit | Included or separate pilot bit for stability during drilling | Medium |

| Compatibility | Ensure compatibility with existing tools (drills) | High |

| Cooling Features | Integrated cooling slots or options for improved longevity | Medium |

When it comes to using door hole saws in various materials, understanding the best practices can significantly enhance your project's efficiency. According to a study by the Home Improvement Research Institute, over 60% of DIY enthusiasts report struggling with drill bit selection and material compatibility, leading to suboptimal results or tool wear. Selecting the right type of hole saw—bi-metal for wood and light metals, and carbide-tipped for harder materials—can mitigate these issues and ensure cleaner cuts while maintaining tool longevity.

Moreover, proper drilling techniques are crucial. The Industrial Manufacturing Engineering journal illustrates that using the correct speed and feed rate for different materials can improve cutting efficiency by up to 30%. For instance, drilling through softwood requires a higher RPM compared to hardwood, which benefits from slower speeds to prevent burning and material splintering. Additionally, using cutting fluids on metals not only prolongs the life of the tool but also enhances the smoothness of the cut. Adhering to these best practices will lead to more effective door hole saw applications and superior project outcomes.

When working with door hole saw applications, several common issues can impede progress and affect the quality of the finished job. One frequent challenge is overheating, which can result in a dull saw and poorly cut holes. To mitigate this, it’s essential to maintain a steady speed and apply consistent pressure while cutting. Additionally, using cutting oil can help reduce friction and heat, extending the life of the saw.

Another issue that may arise is misalignment during the drilling process. This often leads to uneven holes that may not fit the intended hardware properly. To address this, ensure that the hole saw is securely attached to the drill and that the drill is held perpendicular to the door surface. Utilizing a pilot bit can also aid in maintaining alignment, providing guidance as you begin to cut. Being aware of these challenges and implementing preventative measures can enhance the efficiency of your door hole saw applications and deliver more precise results in your projects.

When it comes to utilizing door hole saws for your projects, maintenance plays a crucial role in maximizing their longevity and performance. According to a report from the National Association of Home Builders, improper maintenance can lead to a decrease in tool lifespan by up to 30%. Regular cleaning and sharpening can significantly enhance cutting efficiency and reduce wear. For instance, lubricating the saw’s teeth with a light oil not only prevents rust but also minimizes friction, allowing for smoother cuts and extended tool life.

Furthermore, it’s essential to monitor the speed and pressure applied during use. The Woodworking Machinery Manufacturers Association suggests operating at optimal speeds tailored for specific materials, as using excessive force can cause overheating and premature dulling of the blades. Investing in quality door hole saws can also yield a remarkable difference; research indicates that high-quality, carbide-tipped saws can last up to five times longer than standard options. By prioritizing maintenance and proper usage techniques, you ensure that your door hole saws remain effective and reliable throughout your projects.