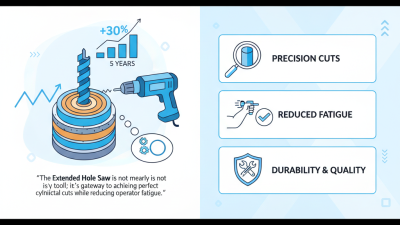

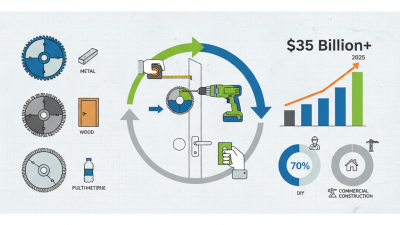

The Carbon Hole Saw is a powerful tool for cutting through hard materials. Its unique design allows for efficient drilling in various applications. According to industry reports, the global market for hole saws is expected to reach $1.3 billion by 2025. This growth reflects the increasing demand for precise and durable cutting tools.

Using a Carbon Hole Saw effectively requires understanding its capabilities and limitations. Many users overlook safety protocols and proper techniques, leading to potential hazards. For instance, using the wrong speed can result in overheating or damaging the saw. A recent survey indicated that over 30% of users experienced issues due to improper use. Awareness of such details can significantly improve performance and safety.

Moreover, preparation is key when using a Carbon Hole Saw. Failing to secure the material or align the saw correctly often leads to wasted materials and time. A carpenter shared that he once wasted several boards due to misalignment. Each cut reminds us how precision matters. By following established tips and being mindful of best practices, users can achieve better results and extend the lifespan of their tools.

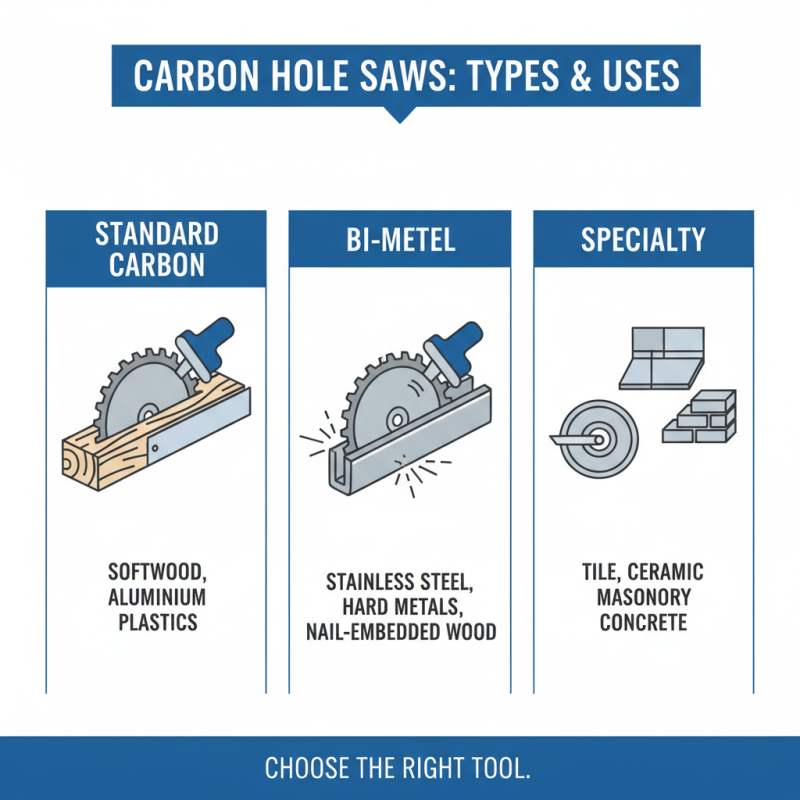

Carbon hole saws are essential tools in woodworking and construction. They come in various types, each designed for specific tasks. Standard carbon hole saws work well for softwood and certain metals. Bi-metal designs are stronger and can cut through stainless steel. There are also specialty saws for tiles and masonry. Understanding these types helps in choosing the right tool for the job.

Using the correct carbon hole saw maximizes efficiency but requires careful consideration. The material of the workpiece matters greatly. If the saw isn't matched with the right material, the results can be disappointing. Painful mistakes can occur, like jagged edges or incomplete cuts. Always check compatibility before starting. The cut depth also needs attention. Too deep, and you risk damaging the workpiece. Frequent pauses during cutting can help prevent overheating, but they might disrupt workflow. Balancing speed with care is vital—quality suffers without it.

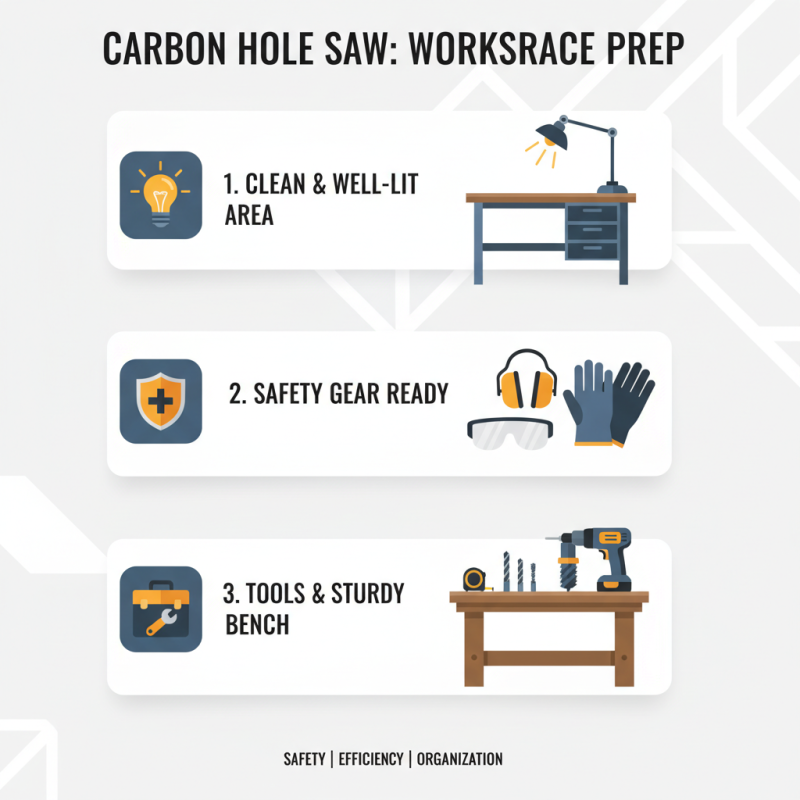

Preparing your workspace for using a carbon hole saw is crucial for both safety and efficiency. Begin by ensuring that your work area is clean and well-lit. A clutter-free space reduces distractions. Make sure you have all necessary tools nearby. This includes your saw, safety gear, and a sturdy workbench. Workspace organization can prevent accidents.

Next, focus on securing your material. Use clamps to hold the workpiece in place. This keeps it stable while cutting. Avoid using your hands to hold it. If the material shifts, it could lead to injury. Always wear protective eyewear and gloves. Small flying debris can cause serious eye injuries. Consider using a dust mask if you’re cutting materials that create harmful particles. Always think about the aftermath and clean up afterward.

Testing the hole saw on scrap material can help you understand its behavior. It's better to make mistakes on something less important. Reflect on what works and what doesn’t. You may need to adjust your technique or workspace setup based on this experience. Stay patient; mastering the use of a carbon hole saw takes time and practice.

When using a carbon hole saw, selecting the correct drill speed is crucial. Too fast, and you risk damaging the bit or the material. Too slow, and you’ll struggle to make progress. Generally, lower speeds suit harder materials, while softer materials allow for higher speeds. For example, drilling through metal may require rates between 300-600 RPM. On the other hand, wood can be drilled at higher speeds, around 1200 RPM.

Testing your approach is essential. Start at a lower speed, then incrementally increase it if needed. Pay attention to the saw’s behavior. If it’s smoking or vibrating excessively, reduce the speed. The sound of drilling can offer clues too; a steady hum indicates a good match. Don't rush. It’s tempting to power through, but patience can lead to cleaner results. Adjustments mid-process can make a big difference. Remember that practice makes perfect. Each material behaves differently. It may take time to get accustomed to these variances.

Maintaining proper pressure during the operation of a carbon hole saw is crucial for achieving clean cuts. Too much pressure can lead to overheating, dulling the blades, or even breaking the saw. Conversely, applying too little pressure can result in an uneven cut or inefficient drilling. It's essential to find that sweet spot. A careful balance ensures the saw performs effectively while prolonging its lifespan.

While cutting, listen to the sounds the saw makes. A consistent humming sound often indicates the right pressure. If you hear a grinding noise, it might be time to reduce your force. Pause occasionally to check the temperature of the saw; if it's too hot to touch, you are likely pressing too hard. Cooling the blade with a bit of lubricant can also help. However, don’t overdo it; excessive lubricant can make the work messy.

One common mistake is rushing the process. Many users think that applying more pressure will speed up the cut. This can lead to mistakes and wasted materials. It’s better to take your time and adjust your force. Familiarize yourself with the material you are cutting. Not all materials behave the same, and what works for one may not work for another. Reflecting on your approach can lead to improvements in your technique.

Maintaining your carbon hole saw is crucial for its longevity. Regularly inspect the saw for wear and tear. Check the teeth for dullness. If they appear damaged, it’s time for replacement. A dull saw can lead to poor cuts and excess heat. That means more effort and less control.

After use, clean the saw thoroughly. Remove any debris or material buildup. Use a soft brush or cloth for this task. Avoid abrasive cleaners that may scratch the surface. Store the saw in a dry place. Moisture can cause rust, quickly deteriorating its effectiveness.

Remember to lubricate the saw periodically. This helps reduce friction during cuts. A few drops of oil can make a difference. Improper storage is a common mistake. Avoid leaving it in a toolbox where it can get damaged. Regular checks and proper care will keep your carbon hole saw in top shape. It’s worth the extra effort.