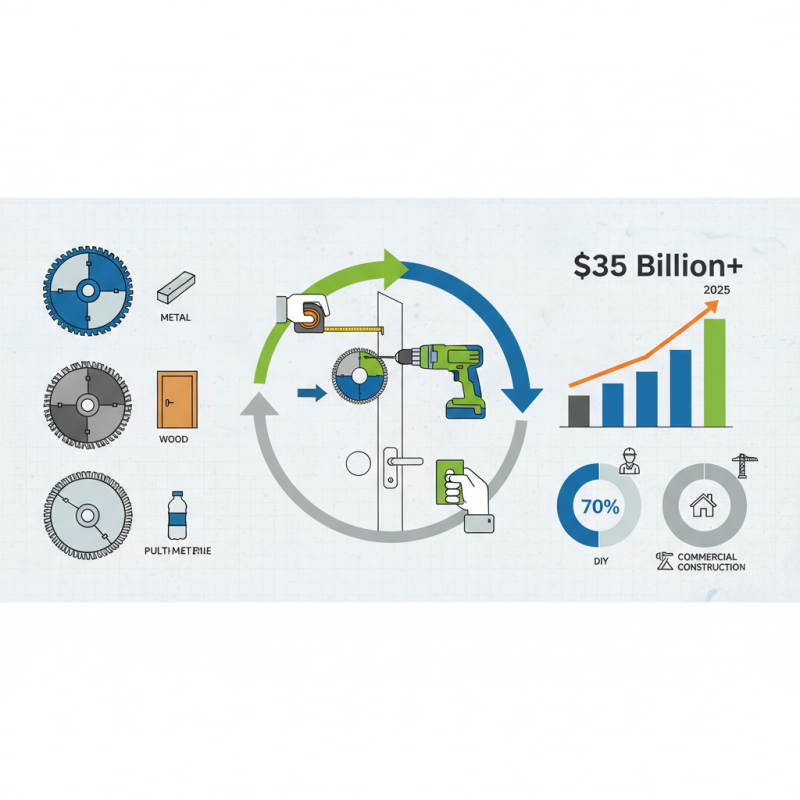

When embarking on projects that require precision and efficiency, the selection of tools is paramount. Among these tools, the "Door Hole Saw" stands out as an essential instrument for creating clean, circular holes in a variety of materials, including wood, metal, and plastic. According to recent industry reports, the global power tool market, which includes hole saws, is projected to reach over $35 billion by 2025, driven by increasing DIY home improvement trends and robust commercial construction activities.

Selecting the right Door Hole Saw not only enhances project outcomes but also improves workflow efficiency. Factors such as blade material, tooth design, and size significantly influence performance, with high-quality saws being able to cut through tough materials effortlessly while minimizing wear and tear. Moreover, studies indicate that 70% of professionals rely on specialized tools to achieve precise cuts, demonstrating the importance of investing in the right equipment for both novice and seasoned users. With this comprehensive guide, we aim to navigate through the vast array of choices available, ensuring that your projects are executed to perfection.

When it comes to tackling door installations or renovations, understanding the various types of door hole saws available is essential for achieving precision and efficiency. Door hole saws are specifically designed to create clean and accurate circular holes for door locks, knobs, and even larger fittings. Generally, these tools come in two primary categories: standard hole saws and recessed hole saws. While standard hole saws are ideal for penetrating flat surfaces like hollow-core doors, recessed hole saws are better suited for creating deeper cuts that accommodate components requiring more room, such as deadbolts.

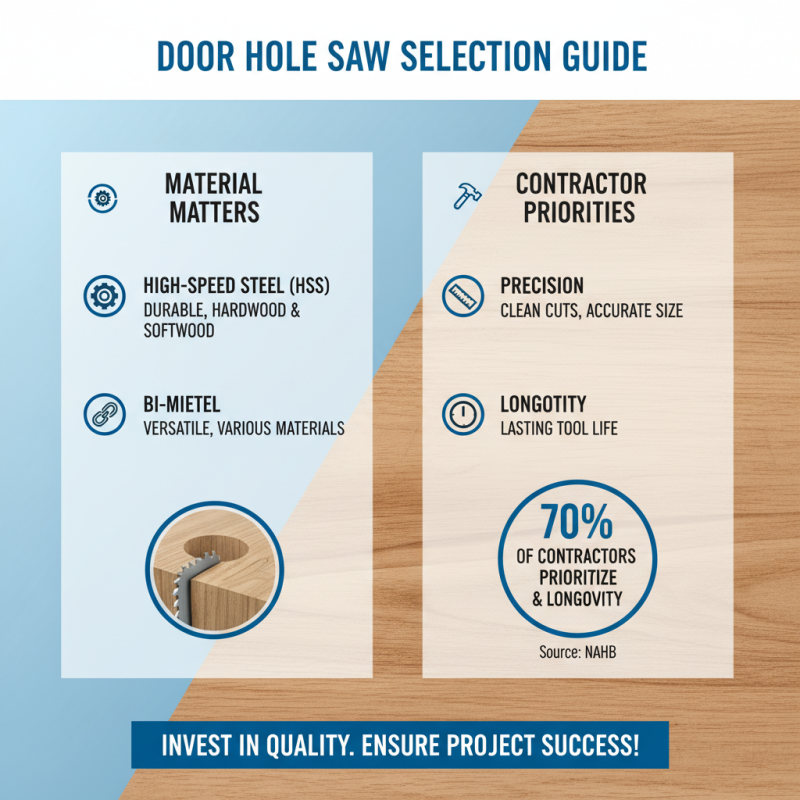

In addition to the types, it's crucial to consider the materials of the hole saws, which can significantly affect performance and durability. Common materials include high-speed steel, bi-metal, and carbide-tipped options. High-speed steel hole saws are ideal for soft to medium density materials, while bi-metal ones offer the versatility to handle both wood and metal doors effectively. Carbide-tipped hole saws provide a longer lifespan and are perfect for tougher materials like fiberglass or dense composite doors. By understanding these distinctions, you can select the right door hole saw that aligns with your project's specific needs and ensure a professional finish every time.

When selecting the best door hole saw for your projects, there are several key factors that demand your attention. Firstly, the material of the hole saw itself is crucial; high-speed steel (HSS) and bi-metal hole saws are popular choices due to their durability and ability to cut through various materials, including hardwood and softwood. According to the National Association of Home Builders, projects involving wood installations have seen a steady increase, with 70% of contractors prioritizing tools that ensure precision and longevity. This highlights the importance of investing in a quality hole saw that meets these criteria.

Another essential factor is the size of the hole saw, which directly influences the breadth of your projects. Most door hole saws come in various sizes, with the most common diameters ranging from 1-3/8 inches to 2-1/2 inches, accommodating standard doorknob and deadbolt installations. A survey conducted by the Home Improvement Research Institute found that 68% of DIY enthusiasts prefer tools that offer versatility in size to tackle multiple job requirements. Furthermore, ease of use and compatibility with your drill type should not be overlooked, as a well-fitting hole saw can significantly improve the efficiency and outcomes of your tasks, ensuring that every door installation is flawlessly executed.

When selecting a door hole saw, evaluating the material and build quality is crucial for ensuring durability and performance. High-quality materials, such as hardened steel or bi-metal construction, often provide greater longevity and resistance to wear. These materials can withstand the rigors of cutting through various types of wood, metal, or even composite materials, ensuring that your project runs smoothly without frequent replacements. The design of the teeth also plays a significant role; sharper, more robust teeth can lead to cleaner cuts and reduce the likelihood of chipping or splintering.

In addition to the material composition, the build quality of the hole saw itself is vital. A well-constructed hole saw should have a sturdy connection to the drill, as a loose fit can cause wobbling and uneven cuts. Examining the welds and seams is also important; poorly constructed joints can lead to premature failure during operation. Ultimately, investing in a high-quality door hole saw made from durable materials will not only enhance your efficiency but also contribute to the overall quality of your projects. Making an informed choice based on these factors will ensure that your hole saw can withstand the test of time and deliver satisfactory results consistently.

Using a door hole saw can seem straightforward, but ensuring safety and efficiency is crucial for achieving perfect results on your projects. Begin by always wearing appropriate safety gear, including goggles and gloves, to protect yourself from flying debris. Set up your work area in a well-lit, clutter-free space to minimize distractions and hazards. Secure the door or material tightly using clamps to prevent movement, which is essential for precision cutting.

When operating the hole saw, maintain a steady and moderate speed to avoid overheating and dulling the teeth of the saw. Applying too much pressure may cause the saw to bind or lead to uneven cuts. Instead, let the tool do the work; a light touch will ensure cleaner holes. To further improve your outcomes, consider using a pilot bit, which helps guide the saw and keeps it centered throughout the process.

**Tips**: Before starting, always drill a test hole in scrap material to ensure that you have the correct depth and placement. Additionally, if cutting through thicker materials, periodically pull the saw out to clear out any debris, which enhances performance and reduces the chances of the saw getting stuck. Following these techniques will empower you to use a door hole saw safely and effectively, allowing for flawless projects every time.

| Hole Saw Size (inches) | Material Type | Ideal Applications | Recommended RPM | Safety Tips |

|---|---|---|---|---|

| 1 | High-Speed Steel | Wood, Soft Materials | 3000-4000 | Always wear eye protection and gloves. |

| 2 | Bi-metal | Wood, Light Metal | 2500-3000 | Ensure the material is secured before cutting. |

| 3 | Carbide-tipped | Hardwood, Composite Materials | 2000-2500 | Use a drill with a depth stop feature. |

| 4 | Diamond-coated | Ceramic, Tile | 1500-2000 | Use water for cooling during drilling. |

| 5 | Steel | Metal Sheets | 1000-1500 | Check for voltage compatibility and avoid overloading. |

To extend the life of your door hole saw, regular maintenance is essential. Start by cleaning the saw after each use to prevent resin and debris build-up, which can affect its performance during future projects. A soft brush or a cloth can effectively remove sawdust and other particles, while soaking the saw in cleaning solution can help dissolve any stubborn residue. Ensuring that the saw is dried thoroughly after cleaning will prevent rust and deterioration of the cutting edges.

Sharpening the teeth of your door hole saw periodically is also crucial in maintaining its effectiveness. Dull blades tend to cause more friction, leading to overheating and potential damage. Using a fine file or a specialized sharpening tool, carefully restore the sharpness of the teeth, ensuring that they maintain their original angle to cut effectively. Additionally, storing the saw in a protective case or a designated spot will prevent accidental damage and keep it ready for your next project. Following these maintenance tips will not only enhance the performance of your door hole saw but also prolong its lifespan, allowing you to achieve perfect results in your woodworking endeavors.