In the ever-evolving world of industrial drilling, the importance of selecting the right equipment cannot be overstated. Specifically, the High Speed Hole Opener stands out as a crucial tool for efficiency and precision in various drilling projects. According to a recent industry report by IBISWorld, the global drilling equipment market has seen an annual growth rate of 3.5% over the past five years, reflecting increased demand for advanced drilling technologies. The right High Speed Hole Opener can significantly enhance productivity by reducing drilling time and improving hole quality, making it essential for operators to understand the diverse types available and their applications.

As we delve into the ultimate guide for choosing the perfect High Speed Hole Opener for your projects, we'll explore key factors such as material compatibility, size specifications, and performance features that can make a substantial difference in project outcomes. Whether you’re tackling commercial construction or specialized engineering tasks, selecting the ideal tool can provide a competitive advantage in today’s fast-paced environment.

When selecting a high-speed hole opener for your project, it’s essential to consider several key factors to ensure optimal performance. First and foremost, the material you're working with should dictate your choice of hole opener. For harder materials such as metal or dense wood, a high-speed steel bit provides durability and efficiency. In contrast, softer materials can be handled with bits specifically designed for quick drilling to save time and effort.

Another critical element to consider is the size of the hole required. Standard measurements often vary, so ensuring that the opener matches your specifications is vital. For projects with varying hole sizes, an adjustable hole opener can add versatility. Additionally, think about the speed and power of the drill you plan to use; a high-speed option will generally yield better results in conjunction with a strong drill.

**Tips:** When choosing a high-speed hole opener, always check the manufacturer’s guidelines for compatibility with your drill. Investing in a quality drill bit can significantly affect the ease and precision of your work. Lastly, remember to keep your bits sharp and clean to maintain drilling effectiveness and prolong their lifespan.

| Feature | Consideration | Recommended Size | Material Type |

|---|---|---|---|

| Cutting Speed | Required RPM for optimal performance | 200 - 1000 RPM | High-speed steel (HSS) |

| Hole Size | Diameter of the hole needed | 1" to 6" | Carbide or HSS |

| Type of Material | Material being drilled through | N/A | HSS, Carbide, or Diamond |

| Cooling Method | Type of cooling used during cutting | N/A | Water or lubricant |

| Desired Finish | Finish quality after drilling | N/A | HSS for smoother edges |

When it comes to drilling applications, selecting the right high-speed hole opener is crucial for efficiency and performance. High-speed hole openers come in various types, each designed for specific materials and purposes. For instance, diamond-tipped hole openers are ideal for hard materials like concrete and brick, while tungsten carbide options are better suited for softer substrates. According to a report by the International Journal of Engineering Research, using the correct type of hole opener can increase drilling speed by up to 30%, significantly enhancing project turnaround times.

In specialized applications, such as when creating holes for plumbing or electrical systems, the choice of a high-speed hole opener can impact not just the drilling speed but also the accuracy required for fit and placement. Research published in the Journal of Construction Engineering highlights that using the right opener can reduce material waste and rework, saving both time and costs, which are vital factors in construction and renovation projects.

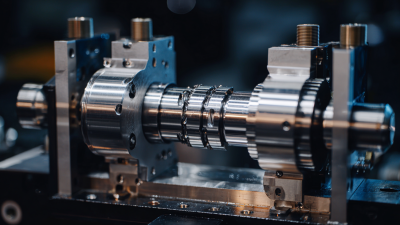

When selecting a high-speed hole opener for your projects, it's crucial to focus on key features that meet your specific needs. First, consider the material of the opener. High-speed steel (HSS) and carbide-tipped versions both have their advantages; HSS is typically more affordable and suitable for softer materials, while carbide is more durable and excels with harder substances.

Next, the size and design of the hole opener are essential. Look for a model that offers a range of diameters to accommodate various hole sizes in your projects. A design that ensures efficient chip removal can also save time and enhance the overall performance during drilling.

Tips: Always check the compatibility of the hole opener with your existing tools, as improper fit can lead to inefficiencies. Additionally, assess the warranty and customer service options offered by manufacturers, as they can provide peace of mind and support for any issues that may arise during use.

When selecting a high-speed hole opener for your projects, maximizing efficiency and performance should be at the forefront of your decision-making process. The quality of contact in any application can significantly influence its overall performance. Just as advancements in organic solar cells underscore the importance of ohmic transitions at contacts to enhance fill factor and efficiency, a high-speed hole opener must feature robust contact points to minimize energy loss during operations, thereby improving throughput.

Moreover, technology in related fields has demonstrated that single-shot systems can achieve near-perfect cluster efficiencies in perforating applications. This principle of maximizing efficiency can be applied when considering the design and operation of high-speed hole openers. Utilizing equipment that minimizes resistance and optimizes fluid dynamics can lead to lower treating pressures, translating to superior performance metrics. Industry reports suggest that strategic upgrades and the integration of advanced materials can yield significant gains, with some systems reporting efficiency improvements of up to 20%, further justifying the importance of informed selection in your hole opening process.

Proper maintenance and care of your high-speed hole opener can significantly extend its lifespan and improve its performance. Regular cleaning after each use is essential. Debris and shavings can accumulate, leading to corrosion and wear over time. Utilize a soft brush or compressed air to remove any residue. Additionally, inspect the cutting edges for any signs of damage or wear. Addressing minor issues promptly can prevent more extensive repairs or replacements down the line.

Proper maintenance and care of your high-speed hole opener can significantly extend its lifespan and improve its performance. Regular cleaning after each use is essential. Debris and shavings can accumulate, leading to corrosion and wear over time. Utilize a soft brush or compressed air to remove any residue. Additionally, inspect the cutting edges for any signs of damage or wear. Addressing minor issues promptly can prevent more extensive repairs or replacements down the line.

Lubrication is another critical aspect of maintenance. Ensuring that the moving parts are adequately lubricated will reduce friction and heat generation during operation. This not only enhances efficiency but also protects the integrity of the hole opener. Consider using a high-quality lubricant that is suitable for your specific type of equipment. Finally, store your hole opener in a dry, temperature-controlled environment to avoid moisture buildup, which can lead to rust and degradation. Following these simple yet effective care tips will help you get the most out of your high-speed hole opener, making it a reliable tool for all your projects.