In the ever-evolving world of DIY home improvement and professional construction, the Door Hole Saw has long been a staple tool for creating precise holes for doorknobs and locks. However, as the demands of global buyers grow and the industry seeks more efficient solutions, it has become evident that traditional Door Hole Saws may not always meet the diverse needs of users. This blog explores innovative alternatives to the conventional Door Hole Saw, addressing the common problems associated with the traditional approach, such as excessive wear, limited versatility, and the challenges posed by different materials. By delving into these alternatives, we aim to enlighten readers on how to enhance their door installation projects, ultimately leading to better performance and satisfaction in their craftsmanship. Join us as we navigate through these exciting innovations tailored for the modern market.

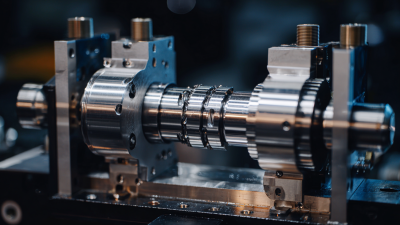

The door hole saw is an essential tool for both professional contractors and DIY enthusiasts. However, traditional steel-based hole saws can sometimes fall short in terms of efficiency and performance. As global buyers seek innovative solutions, alternative materials have emerged to enhance the cutting experience. For instance, carbide-tipped and diamond-coated hole saws offer improved durability, allowing for cleaner cuts in various materials, from wood to metal and even ceramic tiles.

In the evolving landscape of hardware tools, the comparison between traditional door hole saws and innovative alternatives is crucial for global buyers. Traditional door hole saws have long been the industry standard, known for their reliability and straightforward design. However, with the continuous growth of disruptive innovation, new products are emerging that enhance efficiency and precision. A recent industry analysis highlights that innovative drill designs can reduce cutting time by nearly 30%, significantly boosting the productivity of both professional contractors and DIY enthusiasts.

One of the most significant advancements is the introduction of multi-use hole saws, which adapt to various materials, eliminating the need for multiple tools. This innovation not only streamlines the process but also reduces costs for users, making it an attractive option in an increasingly competitive market. Additionally, AI-driven technologies are now being integrated into tool design, allowing for smarter features such as automated depth control and real-time material detection.

**Tips:** When considering new door hole saw options, prioritize products that offer versatility and time-saving features. Always assess the material compatibility of the saw to ensure it meets your project requirements. Lastly, look for tools with positive user reviews that reflect durability and performance, as these are strong indicators of industry credibility.

| Category | Traditional Door Hole Saws | Innovative Alternatives |

|---|---|---|

| Material | High-Speed Steel (HSS) | Carbide-Tipped |

| Cutting Depth | Up to 2-3/8" | Adjustable (up to 5") |

| Weight | 1 - 2 lbs | 0.5 - 1.5 lbs |

| Cutting Speed | Moderate | High |

| Cost | $15 - $30 | $25 - $50 |

| Usage | Best for Softwood | Suitable for Hardwood & Composite |

When exploring alternative tools for door hole saws, it’s important to understand the unique needs of your project. The variety in materials, sizes, and design will influence your choice of tool. Begin by assessing the primary material you will be working with—whether it’s wood, metal, or another substance—as different materials require specific cutting techniques and tools.

Tips:

In the realm of DIY projects and home renovations, the choice of tools can significantly impact the outcome of your work. Many users are now turning to innovative door hole saw alternatives that cater to both efficiency and precision. One such tool that has garnered attention is the adjustable hole saw, which allows for seamless adjustments to various door thicknesses. Users report that this flexibility not only saves time on switching tools but also enhances the quality of their cuts, minimizing the need for excessive touch-ups.

When exploring these alternatives, it's essential to consider your specific needs. For instance, materials like laminate require different cutting approaches compared to solid wood. A tip for maximum effectiveness is to pair your chosen saw with a quality drill — ensure it's powerful enough to handle the resistance of thicker materials. Additionally, using a lubricant during the cutting process can help maintain the tool's longevity and improve the cutting performance.

User experiences highlight the value of trying out these alternative saws in diverse applications, from replacing old doors to crafting custom furniture. Those who have embraced these tools appreciate the balance they strike between ease of use and professional-grade results. As more buyers explore these options, sharing real-world applications can help others determine which innovative saw best suits their projects.

As global buyers seek innovative alternatives to traditional door hole saws, it's essential to understand how to maintain these products for longevity. Recent insights from industry experts highlight that enhancing the durability of alternative saw options not only maximizes performance but also reduces overall costs. According to a report by the International Association of Saw Manufacturers, alternative materials can provide up to 30% longer lifespan compared to conventional steel saws when properly maintained.

To ensure your alternative saw options remain efficient, regular maintenance is crucial. Here are a few tips: First, always clean the saw after each use to remove any debris or pitch buildup; this helps prevent rust and maintains cutting efficiency. Additionally, store the saw in a cool, dry place to avoid moisture damage, which can significantly affect the material's integrity. Finally, periodically check for any signs of wear and replace components as necessary to avoid diminished performance.

By embracing these maintenance practices and leveraging innovative materials, buyers can enjoy the benefits of longer-lasting, high-performance door hole saw alternatives, contributing to both sustainability and cost-effectiveness in their projects.