Using a Large Hole Saw can be a game changer for woodworking and construction projects. It's essential for creating precise holes in various materials. However, many users struggle with proper techniques and safety. Mistakes can lead to wasted materials and unsafe conditions.

When operating a Large Hole Saw, preparation is key. Understanding the right speed and pressure can make a significant difference. Using the correct pilot bit is vital for stability. Without it, the saw can slip, causing frustration. This tool can create clean cuts, but it requires more than just good intentions.

Safety is paramount. Wearing the right protective gear is crucial. Yet, many overlook this step. Unforeseen accidents can happen even to the experienced. A simple lapse in focus can lead to injury. By being mindful and informed, you can harness the power of a Large Hole Saw effectively.

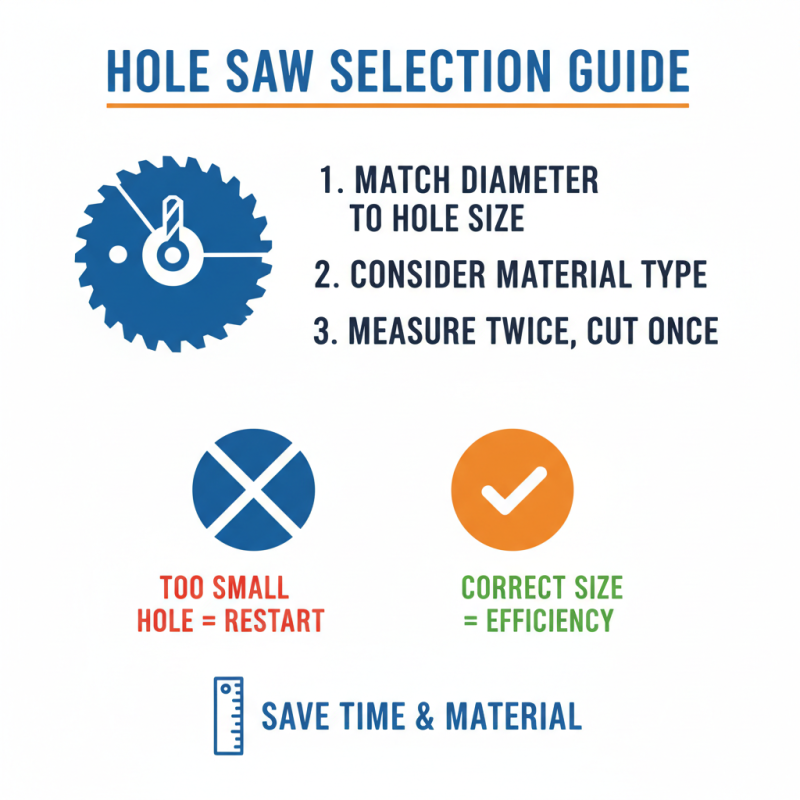

When using a large hole saw, understanding the basics is crucial. These saws are designed to cut large, clean holes in various materials. Common materials include wood, drywall, and plastic. Start by selecting the appropriate size for your project. Measure twice, cut once. An inaccurate measurement can lead to wasted materials and time.

Next, ensure you have the right drill and speed settings. A powerful drill is essential. Too slow can overheat the saw. Too fast might damage it. Use a steady hand to guide the saw. Uneven pressure can result in a crooked hole. Pay attention to the sparks and debris. They indicate how the material interacts with the saw.

Safety is paramount. Always wear safety goggles to protect your eyes. Dust can fly up, and pieces may break off. It’s necessary to check the setup frequently. Loose connections can lead to accidents. If you feel resistance, pause and reassess. It’s better to stop than to push through and risk damage. Mistakes happen; they are part of the learning process. Each project teaches you something new.

Choosing the right size and type of hole saw is crucial for any project. A large hole saw can create significant cuts in various materials. The diameter of the saw should match the size of the hole you intend to cut. Misjudging this can lead to wasted materials and time. Measure twice before making a selection. If the hole is too small, you'll have to start over.

Consider the material you'll be cutting. Different hole saws are designed for specific tasks. Wood, metal, and masonry require different styles. It's essential to select a hole saw that matches the material to ensure a clean cut. A wrong choice can lead to dull blades and poor results. You might get frustrated when the saw binds or burns.

Sometimes, you may find that you have the right size, but not the right type. This creates complications. Struggling with a dull saw, you might ruin the piece you're working on. It can be disheartening. A small inspection beforehand can prevent this. Having the right tool makes a significant difference in your work quality. Don't overlook the details, they matter more than you think.

When preparing your material for using a large hole saw, several factors come into play for optimal results. Ensure the surface is flat and stable. A wobbly surface can cause uneven cuts. Use clamps to secure the material. This step might feel tedious, but it's crucial for safety and precision.

Another essential tip involves selecting the right speed. Too fast can lead to overheating. Exhaustion can reduce your efficiency and quality. A moderate speed allows the saw to cut through the material more effectively. Test different speeds if you’re unsure. This process requires patience, as hurrying may lead to frustration.

Also, always mark the drilling point. Use a center punch or a simple marker. This small act dramatically improves accuracy. It helps in maintaining focus while cutting. Remember, mistakes can occur, so slow down and reflect on your technique. Adjusting to different materials requires practice. Embrace these challenges, as they refine your skills over time.

Using a large hole saw effectively can dramatically improve your drilling projects. The right technique is essential to achieve cleaner cuts and extend the life of your tool. Industry reports suggest that improper usage can reduce efficiency by over 30%. So, let's explore some key techniques to enhance your performance.

Begin by ensuring your drill is stable. A wobbly drill can cause uneven cuts and damage both the saw and the material. Keep your eyes on the alignment. A misaligned saw often results in jagged edges. According to the latest studies, nearly 25% of users report issues due to alignment errors.

Use slow and steady pressure while drilling. Too much force can overheat the saw, especially in dense materials. An interesting finding from a recent survey shows that 45% of professionals adjust their speed based on the thickness of the material. Remember, patience pays off. After each cut, allow the saw to cool down; this helps maintain its longevity. Good techniques not only save time but also enhance precision.

| Tip | Description | Tool Maintenance | Safety Precautions |

|---|---|---|---|

| Select the Right Size | Choose a hole saw that matches the diameter needed for your project. | Keep the saw teeth sharp and free of debris for better performance. | Wear safety goggles and gloves to protect eyes and hands. |

| Drill with the Right Speed | Use a slower speed for larger bits to prevent overheating. | Regularly check for wear and replace when necessary. | Ensure the material being cut is secured firmly to prevent movement. |

| Use a Pilot Bit | A pilot bit helps guide the hole saw and creates a cleaner cut. | Lubricate the saw with cutting oil for smoother operation. | Keep hands and loose clothing away from moving parts. |

| Clear Debris Regularly | Stop periodically to remove shavings for better visibility and cutting efficiency. | Store in a dry place to prevent rust. | Use a dust mask to avoid inhaling wood or material particles. |

| Practice on Scrap Material | Practicing on scrap helps to understand the tool and reduce mistakes. | Inspect the hole saw before use to check for cracks. | Ensure the work area is clear of hazards. |

When using a large hole saw, maintaining and storing it properly is crucial for its longevity. After each use, clean the hole saw thoroughly. Debris can cause rust and damage. A simple rinse with water and a brush can do wonders. Dry it completely before storing, ensuring no moisture remains.

Consider storing your hole saw in a designated toolbox. A protective case can prevent physical damage. Place it in a dry area to avoid corrosion. Even a slight dent can affect its performance during cutting.

Tips: Always check the teeth of your hole saw. If they are dull or chipped, sharpness will suffer. A dull saw requires extra effort and can lead to frustration. Also, inspect the arbor regularly. A loose connection can result in uneven cuts. If you spot any signs of wear, it’s time for a replacement. Taking care of these details can save you time and effort in future projects.