When it comes to woodworking and construction, selecting the right tools is crucial. One tool that stands out in versatility and efficiency is the Adjustable Hole Saw. Recent industry reports indicate that the global market for hole saws is projected to grow significantly, driven by increasing construction activities and DIY projects. Adjustability in hole saws allows for precision and ease in creating holes of various sizes.

Adjustable Hole Saws offer unique advantages. They can quickly switch between different diameters, saving time and reducing the need for multiple tools. Research shows that professionals value time efficiency, with over 70% expressing a desire for tools that enhance productivity. However, not all adjustable designs meet quality standards. Some may offer great versatility but compromise on durability.

In a market filled with options, it is essential to identify reliable models. The right adjustable hole saw can make a significant difference in performance. Yet, many users overlook proper maintenance and usage guidelines, leading to frustrations. Attention to detail in tool selection can lead to better results and satisfaction in projects.

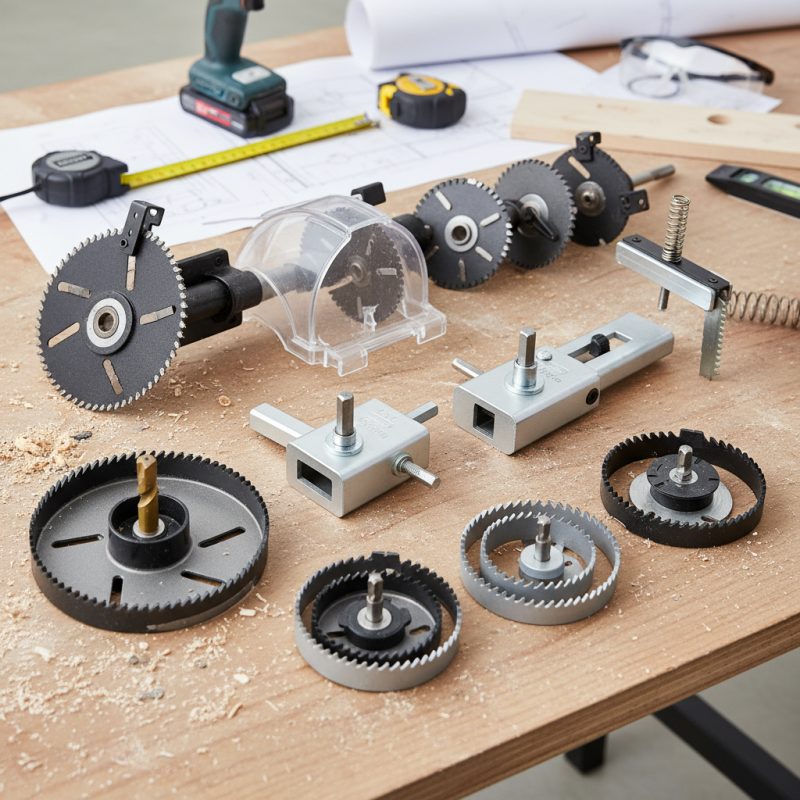

Adjustable hole saws are versatile tools for various applications. They allow users to cut holes of varying diameters, which is beneficial for woodworking and plumbing. This adaptability makes them popular among DIY enthusiasts and professionals alike. When you need to create different-sized openings, adjustable hole saws are the answer.

These tools can tackle many materials, including wood, metal, and plastic. Their design often features a central drill bit with a circular cutting edge. Users can adjust the size by changing the position of the cutting edge. This ability to fine-tune the size is useful for projects like installing locks or running pipes. However, one must be cautious when using them. Improper adjustments can lead to uneven cuts.

The learning curve can be steep for beginners. There are times when the saw might bind or snag, resulting in frustration. Additionally, ensuring safety while operating is crucial. Wearing appropriate gear should never be overlooked. Remember to check the tool frequently for wear and tear. A well-maintained adjustable hole saw can make the difference between a clean cut and a messy job.

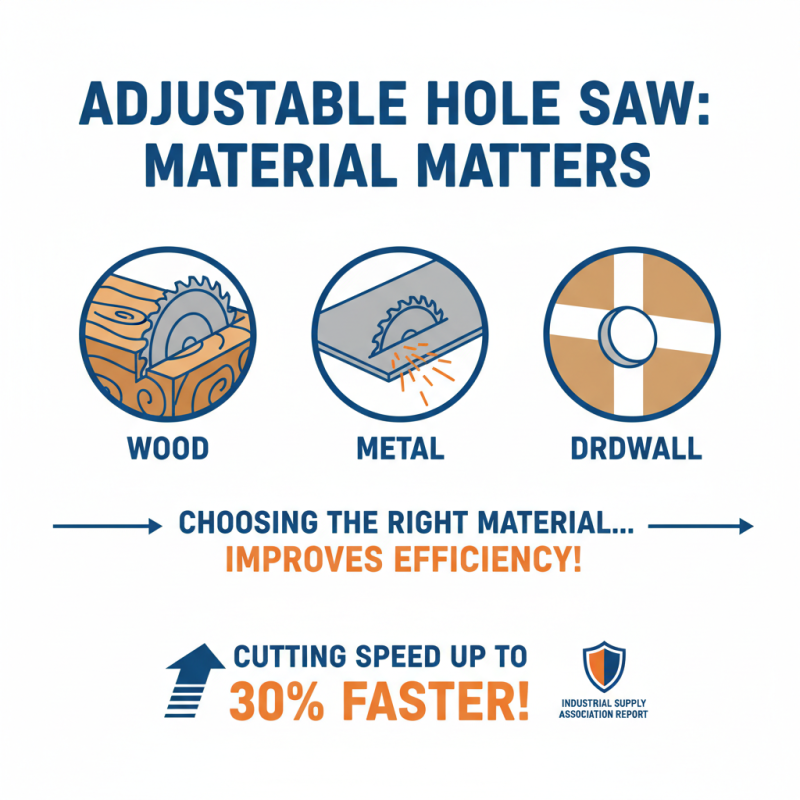

When choosing an adjustable hole saw, considering the material is crucial. Most hole saws are designed for wood, metal, or drywall. Selecting the right material impacts efficiency. A report from the Industrial Supply Association indicates that using the appropriate saw for specific materials can improve cutting speed by up to 30%.

Another key feature is the diameter range. Adjustable hole saws can vary significantly in size. Some models offer diameters from 1 inch to 6 inches. This versatility allows for more project flexibility, especially in complex tasks. Be aware that some designs may struggle with thicker materials, leading to uneven edges. According to a survey by the Power Tool Institute, over 40% of professionals report challenges with diameter adjustments affecting their work quality.

Ease of use is essential too. Features like an easy-to-read scale for depth adjustments are important. Poor ergonomics may lead to fatigue and decrease productivity. A construction industry trend report noted that tools designed with user comfort in mind can boost work rate by 15%. However, not all models provide this, and users often overlook this aspect. Such details can make or break your project.

When it comes to drilling holes, adjustable hole saws are essential tools. They provide flexibility for various projects, allowing users to create different hole sizes with ease. Choosing the right one can be challenging. Pay attention to materials and design.

When selecting an adjustable hole saw, consider the material of the blades. High-quality steel offers durability. However, some may rust quickly. Look for coatings that resist corrosion. Proper maintenance extends their lifespan significantly. Additionally, check the adjustment mechanism. A smooth operation is key! Many models may fail at this point.

Tip: Always wear safety goggles when using hole saws. The debris can be hazardous. Start with slower speeds to minimize damage to surfaces. Avoid pushing too hard; this may cause the blade to bind.

Another aspect to consider is the size range of the hole saw. Some models only offer a limited range. This can be frustrating during projects requiring various sizes. Measure your needs beforehand to avoid regrets. Finding an adjustable hole saw that balances versatility and practicality is a worthwhile endeavor.

Maintaining adjustable hole saws is essential for longevity. Regular cleaning is a simple yet effective way to extend their life. After each use, remove debris and buildup. This prevents material from hardening on the saw. Studies show that proper maintenance can improve tool life by up to 30%.

Lubrication is another critical factor. Applying cutting oil reduces friction during operation. It helps avoid overheating, which can warp your saw. The right lubricant can increase cutting efficiency dramatically. In fact, tools that are well-lubricated perform better and cut cleaner.

Storage conditions also play a role. Keep your hole saws in a dry, cool place. Humid environments can lead to rust, degrading performance. Using a protective case can help. Regularly check the condition of the saw. Any signs of wear should prompt immediate replacement. A proactive approach not only saves money but also enhances work quality.

| Hole Saw Diameter (inches) | Material | Adjustable Range | Typical Applications | Maintenance Tips |

|---|---|---|---|---|

| 1.5 - 3.0 | Bi-metal | Adjustable | Wood, PVC | Keep clean, lubricate |

| 2.0 - 4.0 | Carbide | Adjustable | Metal, Fiberglass | Avoid overheating, store properly |

| 1.0 - 2.5 | High-speed Steel | Fixed | Wood | Regularly check for dullness |

| 1.5 - 3.5 | Diamond | Adjustable | Tile, Stone | Use water for cooling, clean after use |

| 1.0 - 2.0 | Bi-metal | Fixed | Plastic, Composite | Inspect for damage, avoid excessive pressure |

| 2.5 - 4.5 | Carbide | Adjustable | Concrete | Use correct speed settings, clean after usage |

| 1.0 - 3.0 | High-speed Steel | Adjustable | Wood, Drywall | Check for wear, store properly |

| 1.5 - 3.5 | Bi-metal | Adjustable | Metal, Wood | Keep dry, check sharpness |

| 1.0 - 3.0 | Diamond | Fixed | Ceramic, Glass | Use in water, clean regularly |

| 2.0 - 4.0 | Carbide | Adjustable | Masonry | Inspect for debris, handle carefully |

When using adjustable hole saws, safety should be your top priority. According to recent industry reports, a significant percentage of injuries in woodworking involve improper tool use. Ensuring proper safety measures can protect you and your workspace. Always wear protective eyewear. This will shield your eyes from flying debris. Gloves can help prevent cuts but avoid loose clothing that may get caught.

Operating an adjustable hole saw requires focus. Keep your work area organized and clear. A clutter-free environment prevents accidents. Before starting, make sure the material is secure. A stable workpiece minimizes the risk of slips. Remember that the saw can generate heat. Let the tool cool down between cuts to avoid burns.

Tips: Always double-check your settings before cutting. This can prevent costly mistakes. Do not rush through your project. Taking your time will enhance accuracy. If you feel tired or distracted, take a break. A moment of rest can greatly improve your safety and precision.