In the world of precise cutting tools, the Carbon Hole Saw stands out as a vital instrument for both amateur and professional craftsmen. As industry expert Dr. Michael Reynolds, a leading authority in cutting technologies, aptly puts it, “The versatility and precision of the Carbon Hole Saw make it an indispensable tool for any serious woodworker or contractor.” With the increasing demand for impeccable finishes and accuracy, selecting the right Carbon Hole Saw has become more crucial than ever in 2023.

This article will explore the top 10 Carbon Hole Saws on the market, highlighting their features and applications to help you make informed choices. From woodworking projects to plumbing installations, the effectiveness of a Carbon Hole Saw is unparalleled, allowing users to achieve clean, precise cuts with minimal effort. Whether you're a professional or a DIY enthusiast, understanding the nuances of these tools is key to enhancing your craftsmanship and achieving outstanding results. Join us as we delve into the leading Carbon Hole Saws designed to elevate your cutting experience this year.

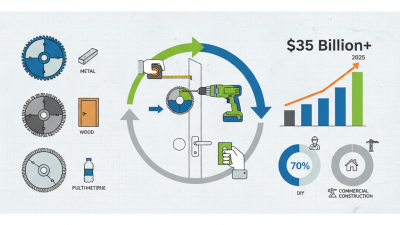

Carbon hole saws are specialized cutting tools designed for precision drilling in a variety of materials, especially in metalworking and construction applications. Defined as cylindrical saws with sharp edges, they are crafted to create perfectly round holes in hard substrates such as stainless steel, aluminum, and plastics. According to a report from the Global Cutting Tools Market, the demand for carbon hole saws has been growing steadily, with a projected compound annual growth rate (CAGR) of 4.5% from 2023 to 2028, driven by advancements in manufacturing technologies and an increase in construction activities.

The applications of carbon hole saws are diverse, from plumbing and electrical installations to automotive and aerospace industries. They are particularly favored for tasks that require precision, such as creating entry points for pipes or wiring. A study by the International Tool Association highlighted that approximately 60% of professionals in the construction sector rely on carbon hole saws for their superior cutting performance and durability. The geometry of these saws allows them to remove material efficiently, reducing the risk of damage to surrounding areas, which is critical in high-stakes environments where accuracy is vital.

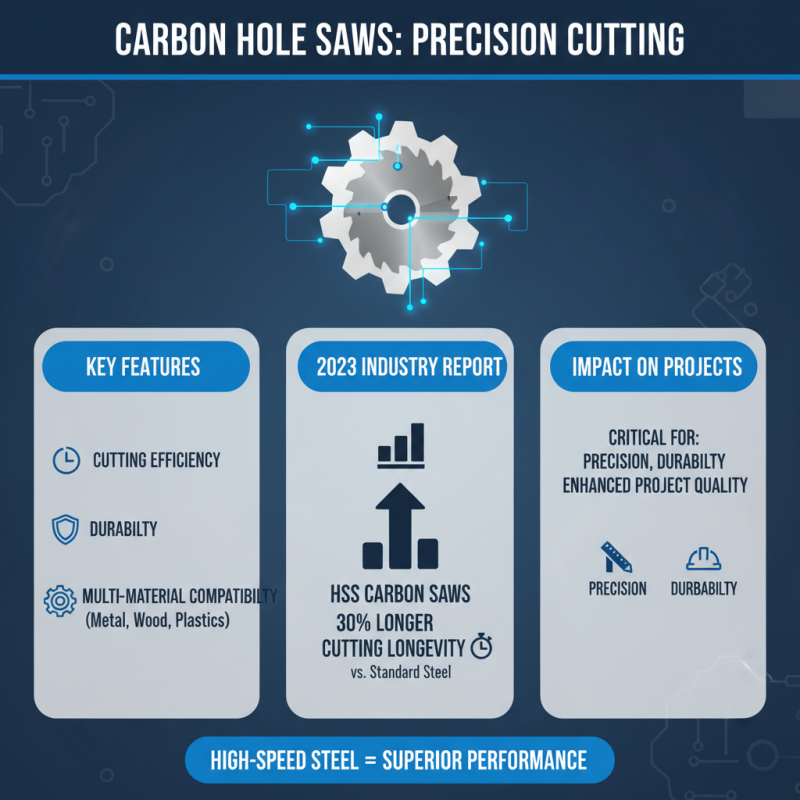

When selecting the right carbon hole saw for your project, it's crucial to consider several key features that will enhance your cutting precision and efficiency. First and foremost, the material composition of the saw plays a significant role in its performance. High-carbon steel and bi-metal hole saws are often preferred for their durability and resistance to wear, which can lead to longer tool life and reduced replacement costs. According to a recent industry report, tools made from premium materials can last up to 50% longer than standard options, providing better value for both professionals and DIY enthusiasts.

Another important feature to evaluate is the tooth design. Hole saws with more teeth can produce smoother cuts and faster drilling times, making them ideal for detailed work. Additionally, the pitch of the teeth influences how well the saw can handle different materials. A finer pitch is better suited for softer materials like wood, while a coarser pitch can efficiently cut through harder substances such as metal or composite materials. This adaptability is essential, especially considering the diverse range of applications in construction and manufacturing sectors.

Tips: Always ensure proper lubrication and cooling when using carbon hole saws, as excessive heat can shorten the life of the tool. Furthermore, it's advisable to use a pilot drill bit to maintain the saw's position and prevent wandering during the initial cut, leading to improved accuracy and cleaner results.

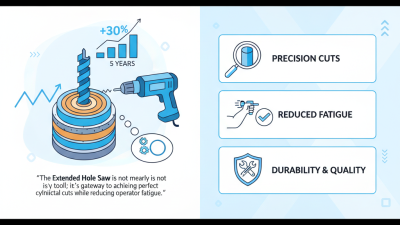

When selecting the best carbon hole saws for precise cutting, it's essential to analyze features such as cutting efficiency, durability, and compatibility with various materials. A 2023 industry report indicates that carbon hole saws made from high-speed steel show a notable increase in cutting longevity, outperforming those constructed from standard steel by up to 30%. This enhanced performance is particularly vital when working with tough materials, such as metal or thick wood, where precision and durability can heavily impact the overall project quality.

Another critical factor in the comparative analysis is the design and size range of the saws. The report emphasizes that hole saws that incorporate optimized tooth geometry lead to improved cutting speed and reduced tear-out. For instance, saws designed with a larger kerf can reduce friction, which in turn lowers the needed cutting force, resulting in cleaner cuts and extended tool lifespan. Furthermore, the versatility of hole saws accommodating various arbor sizes has significantly grown, aligning with a 25% increase in demand for customized solutions in the marketplace.

Investing in quality carbon hole saws not only streamlines the cutting process but also enhances safety and reduces waste. As the construction and DIY industries evolve, the demand for precise tools like carbon hole saws continues to drive innovation, making a thorough analysis essential for both professionals and enthusiasts alike.

When it comes to precise cutting, carbon hole saws have established themselves as essential tools in various industries. According to recent industry reports, the demand for high-quality cutting tools has surged by approximately 15% in 2023, driven by advancements in materials and technology. Users consistently praise carbon hole saws for their longevity and ability to maintain sharpness, reducing the frequency of replacements and ensuring efficiency on the job site. Many professionals report that investing in a top-tier carbon hole saw leads to cleaner cuts and minimized material waste, which is particularly critical in precision-sensitive applications.

Expert recommendations underline the importance of choosing hole saws based on specific cutting needs, material types, and cutting depths. Reviews indicate that models with enhanced arbor designs provide better stability and performance, particularly when used on harder materials, such as metal and composite surfaces. A survey conducted by a leading industry publication revealed that over 80% of users found marked improvements in cutting speed and accuracy when transitioning to high-performance carbon hole saws. As the market continues to evolve, these tools are becoming integral in ensuring optimal results across various projects, whether in construction, woodworking, or metalwork.

To ensure the longevity and optimal performance of carbon hole saws, proper maintenance is essential. After each use, it’s crucial to clean the saws thoroughly to remove any debris or material buildup. This can be done using a soft brush or cloth to wipe the teeth and body, ensuring that no remnants obstruct future cutting. Additionally, soaking the saws in soapy water and using a gentle scrub can help dissolve stubborn residues. Regular cleaning not only maintains precision but also prevents rust formation that can compromise the integrity of the cutting edges.

Another important practice is to store carbon hole saws correctly. After cleaning, they should be placed in a dry environment away from moisture to reduce the risk of corrosion. Using a dedicated storage case can further protect the delicate teeth from physical damage. It’s also wise to periodically inspect the saws for any signs of wear or damage. If any teeth are chipped or worn down, they should be replaced promptly to avoid compromising the quality of cuts on future projects. By following these maintenance tips, users can significantly extend the life of their carbon hole saws, ensuring precise and efficient cutting for many projects to come.