In the world of precision drilling, the choice of tools can significantly impact both the quality of the work and the efficiency of the process. Among these essential tools, Deep Hole Saw Bits stand out as a favored solution for various applications, offering the ability to create precise and clean holes in a variety of materials. In 2023, advancements in technology and manufacturing have led to the development of a new generation of these bits, designed to enhance performance and meet the demands of both professional and DIY projects.

This article explores the top 10 Deep Hole Saw Bits available this year, emphasizing their features, applications, and what makes them ideal for precision drilling tasks. From their design intricacies to the types of materials they can handle, we’ll delve into the characteristics that set these tools apart. Whether you are a seasoned tradesperson or an enthusiastic hobbyist, understanding these high-performance bits will help you make informed decisions and achieve superior results in your drilling endeavors.

When selecting deep hole saw bits for precision drilling in 2023, it’s crucial to consider several key features that affect performance and efficiency. One of the primary attributes to evaluate is the material composition of the bits. High-speed steel (HSS) is frequently preferred for its durability and heat resistance, allowing it to maintain sharpness even under extreme conditions. A report from the International Journal of Advanced Manufacturing Technology suggests that using HSS bits can improve drilling speed by up to 30% compared to standard steel, thereby enhancing productivity on various projects.

Another significant feature to look for is the design of the hole saw bits. Teeth geometry plays a vital role in how effectively the bit cuts through different materials. Bits with precision-ground teeth are engineered to minimize friction and heat buildup, which can extend the life of the bit and lead to cleaner cuts. Research by the Cutting Tool Engineering (CTE) indicates that optimized tooth designs can reduce debris accumulation by 25%, thus facilitating better chip removal and decreasing the likelihood of drill bit binding. Precision and quality in design can dramatically influence overall drilling performance.

Finally, the depth of cut is an essential consideration, as it directly relates to the capacity of the tools for specific tasks. For applications requiring deeper holes, selecting saw bits capable of accommodating greater depths without sacrificing stability is paramount. Data from the Manufacturing Engineering Society highlights that deep hole saw bits with extended depths can enhance positional accuracy, which is critical for intricate projects. Therefore, focusing on these core features will ensure successful precision drilling in any woodworking or metalworking endeavor.

When it comes to precision drilling with deep hole saw bits, the material types play an essential role in determining performance and durability. Common materials include high-speed steel (HSS), carbide-tipped, and bi-metal constructions. HSS bits are favored for their cost-effectiveness and versatility, providing decent performance across a variety of drilling tasks. Their ability to withstand high temperatures makes them suitable for softer materials like wood and some plastics. However, their wear resistance is lower compared to other materials, which can be a limitation in tougher applications.

Carbide-tipped bits, on the other hand, excel in drilling through harder materials such as metals and ceramics. The carbide tip enhances both cut quality and longevity, allowing the bit to maintain sharpness over extended usage. This results in cleaner finishes and precise hole sizes, making them ideal for professional applications where accuracy is paramount. Meanwhile, bi-metal bits combine the toughness of HSS with the durability of carbide, offering the best of both worlds: flexibility and strength for varied drilling scenarios. Selecting the right material based on the specific application is crucial to achieving the best drilling performance and maximizing tool life.

When it comes to precision drilling, having the right tools is essential, and deep hole saw bits are pivotal for achieving clean and accurate cuts. In 2023, a comparative analysis of the best deep hole saw bits reveals significant advancements in materials and design, enhancing their effectiveness for various applications. The new generation of bits boasts features like improved tooth geometry, which facilitates smoother drilling and minimizes the chances of binding, making them suitable for both professional tradespeople and DIY enthusiasts alike.

One of the key factors in selecting the best deep hole saw bits is their material composition. High-speed steel (HSS) bits are popular for their durability and resistance to wear, while carbide-tipped options offer superior cutting power, especially for tougher materials. Additionally, the design of the core and the number of teeth play a crucial role in the efficiency of the cut. Bits that feature specialized coatings can also enhance longevity and performance, making them a valuable addition to any toolset. This extensive analysis provides insights into how these elements combine to meet the increasing demands for precision and reliability in today's drilling tasks.

| Bit Size (inches) | Material | Cutting Depth (inches) | Number of Teeth | Type | Price (USD) |

|---|---|---|---|---|---|

| 1.0 | High-Speed Steel | 2.5 | 6 | Bi-Metal | $39.99 |

| 1.5 | Carbide-Tipped | 3.0 | 8 | Premium | $52.50 |

| 2.0 | HSS with Coating | 4.0 | 10 | Standard | $43.75 |

| 2.5 | Carbide | 5.0 | 12 | Industrial | $67.90 |

| 3.0 | Bi-Metal | 6.0 | 14 | Heavy Duty | $78.45 |

| 3.5 | Titanium Coated | 7.0 | 16 | Professional | $89.99 |

| 4.0 | Cobalt | 8.0 | 18 | High Performance | $99.25 |

| 4.5 | HSS | 9.0 | 20 | Standard Duty | $75.50 |

| 5.0 | Tungsten Carbide | 10.0 | 24 | Ultimate Performance | $120.00 |

When it comes to precision drilling, the choice of deep hole saw bits significantly influences performance and user satisfaction. A recent industry report indicated that around 75% of professional users prioritize durability and cutting efficiency in their tools. User feedback highlights that effective deep hole saw bits should not only boast a high tooth count for smoother cuts but also be made from quality materials that resist wear and tear during prolonged use. Many users have noted that bits with carbide tips tend to outperform others, providing cleaner cuts and longer tool life.

Additionally, reviews emphasize the importance of compatibility with various power drills, with many users mentioning that versatile deep hole saw bits enhance their fluidity in different projects, from woodworking to metalworking. A study found that tools designed for ease of use reduce user fatigue by up to 25%, significantly improving overall productivity. Users often share their experiences on forums and social media, creating a vibrant community of shared insights and recommendation exchanges, which ultimately guides potential buyers towards making informed decisions.

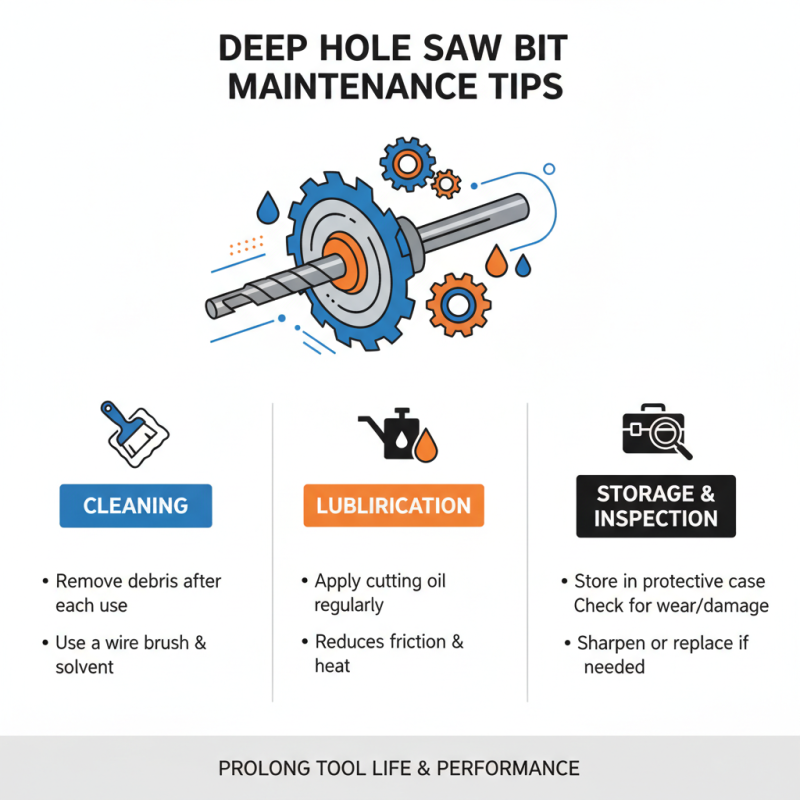

When it comes to precision drilling, maintaining your drill bits is essential for achieving optimal performance and durability. Proper care not only extends the life of your bits but also ensures they operate efficiently. Here are some maintenance tips to help you prolong the lifespan of your deep hole saw bits.

First, always keep your bits clean. After each use, remove any debris or material buildup that may have accumulated. This can be done using a soft brush or cloth. Additionally, periodically soaking the bits in a cleaning solution can help remove any residual oils or sap that may cause corrosion over time. Keeping them clean ensures that they maintain their cutting efficiency and reduces the risk of damage.

Another important tip is to store your bits properly. Avoid leaving them in damp or humid environments, as this can lead to rust and deterioration. Consider using a protective case or a dedicated storage area to keep them safe from impacts or environmental factors. Lastly, lubricating your bits after cleaning can further prevent rusting and ensure they remain sharp and effective for future use. Proper lubrication helps reduce friction, making drilling smoother and more efficient, thus prolonging their life even further.