In the evolving landscape of drilling solutions, the significance of selecting the right tools cannot be overstated. A key player in this domain is the "Hole Opener," which serves as an essential component for enhancing drilling efficiency. As noted by Dr. William Hartman, a leading expert in drilling technology, "The effectiveness of a drilling operation often hinges on the tools we choose; a well-designed hole opener can significantly reduce time and costs."

Over the years, the industry has witnessed transformative advancements in hole opener technology, leading to improved precision and performance. This article delves into the top 10 hole openers available today, showcasing their unique features and the techniques that can optimize their use. Understanding these innovations is crucial for drilling engineers and contractors who aim to stay ahead in a competitive market.

As we explore these tools, it becomes evident that the right hole opener not only facilitates efficient drilling but also contributes to the overall success of projects across various sectors. With this guide, practitioners will gain insights into how to select and implement these essential tools effectively.

Hole openers play a vital role in the drilling industry, designed to enlarge pre-existing holes or create new ones with precision and efficiency. These specialized tools can facilitate various drilling operations, from oil and gas exploration to civil engineering projects. By using a hole opener, operators can improve drilling performance, reduce costs, and enhance overall project timelines. Their importance lies not only in their ability to expedite operations but also in ensuring the structural integrity of the drilled holes, which is crucial for safety and effectiveness in subsequent drilling stages.

When selecting a hole opener, consider the geological conditions you will be facing. Heavy rocks may require more robust designs, while softer soils might benefit from lighter, more versatile options. Additionally, ensure that your hole opener is compatible with the drilling rig or equipment you are using to optimize performance.

Tips: Regularly inspect your hole openers for wear and tear. This practice can help you identify potential issues before they escalate, ensuring that you maintain efficiency throughout your drilling operations. Keeping a maintenance schedule can also prolong the lifespan of your tools and save costs in the long run. Always stay updated on the latest techniques and advancements in hole opening technologies to maximize your drilling effectiveness.

This chart displays the efficiency ratings of various types of hole openers used in drilling operations. Each type is rated based on its effectiveness in providing efficient drilling solutions.

When it comes to efficient drilling solutions, selecting the right type of hole opener is crucial for optimizing performance and enhancing productivity. Hole openers come in various designs, each tailored for specific applications. For instance, two-cone and three-cone bit types are common, known for their durability and effectiveness in drilling tougher materials. Additionally, specialized hole openers like expandable and PDC (Polycrystalline Diamond Compact) bits are designed for precise applications where standard bits may fall short. Understanding these designs allows operators to choose the best tool for their specific project needs.

Tips for selecting a hole opener include considering the geological conditions of the drilling site. Soft formations may benefit from simpler designs, while harder rock types typically require more sophisticated openers. It's also essential to evaluate the diameter and depth of the desired hole, as some hole openers are specifically engineered for wider or deeper applications. Regular maintenance and checks on the equipment can prevent downtime and ensure that the chosen tool performs optimally throughout the drilling process.

Choosing the appropriate hole opener not only enhances drilling efficiency but also prolongs the lifespan of the equipment. Operators should stay informed on the latest innovations and design advancements in hole openers to ensure they are utilizing the best technology available.

| Type of Hole Opener | Diameter Range (inches) | Application | Material | Advantages |

|---|---|---|---|---|

| Tapered Hole Opener | 6 - 54 | Oil and Gas Exploration | High-Grade Steel | Efficient cutting, high durability |

| Hybrid Hole Opener | 8 - 36 | Geothermal Drilling | Composite Materials | Lightweight, high efficiency |

| PDC Hole Opener | 6 - 40 | Mineral Exploration | Diamond Coated | Long life, fast penetration |

| Expandable Hole Opener | 8 - 20 | Water Well Drilling | Alloy Steel | Versatile, easy to transport |

| Underreamer Hole Opener | 10 - 30 | Pipeline Installation | Tool Steel | Increased hole size, cost-effective |

| Fixed Hole Opener | 4 - 14 | Environmental Sampling | Carbon Steel | Simple design, reliable |

| Coring Hole Opener | 4 - 12 | Civil Engineering | Stainless Steel | Precise sampling, corrosion-resistance |

| Jet Hole Opener | 8 - 24 | Geotechnical Surveys | Aluminum | Enhanced flushing, low weight |

| Recessed Hole Opener | 10 - 32 | Trenchless Technology | Heat-Treated Steel | Optimal for tight spaces, robust |

| Dual-Diameter Opener | 6 - 26 | Mining | Special Alloy | Flexible use, reduced wear |

When selecting a hole opener for efficient drilling operations, there are several key features that should be carefully considered to ensure optimal performance. First and foremost, the size and type of the hole opener are crucial. Depending on the specific application and the materials being drilled through, choosing the right diameter and style will significantly impact drilling efficiency. For instance, larger hole openers can facilitate quicker material removal in large diameter applications, while more specialized designs may be necessary for unconventional geological formations.

Additionally, the material construction and wear resistance of the hole opener play a vital role in its longevity and effectiveness. Options may include various grades of steel or carbide inserts that offer durability and the ability to withstand harsh drilling environments. It is also essential to consider the design features, such as the number and configuration of teeth, which influence cutting efficiency and overall performance. Finally, ease of maintenance and the ability to replace components without extensive downtime can streamline operations and reduce costs, making these practical features critical when deciding on the right hole opener for any drilling project.

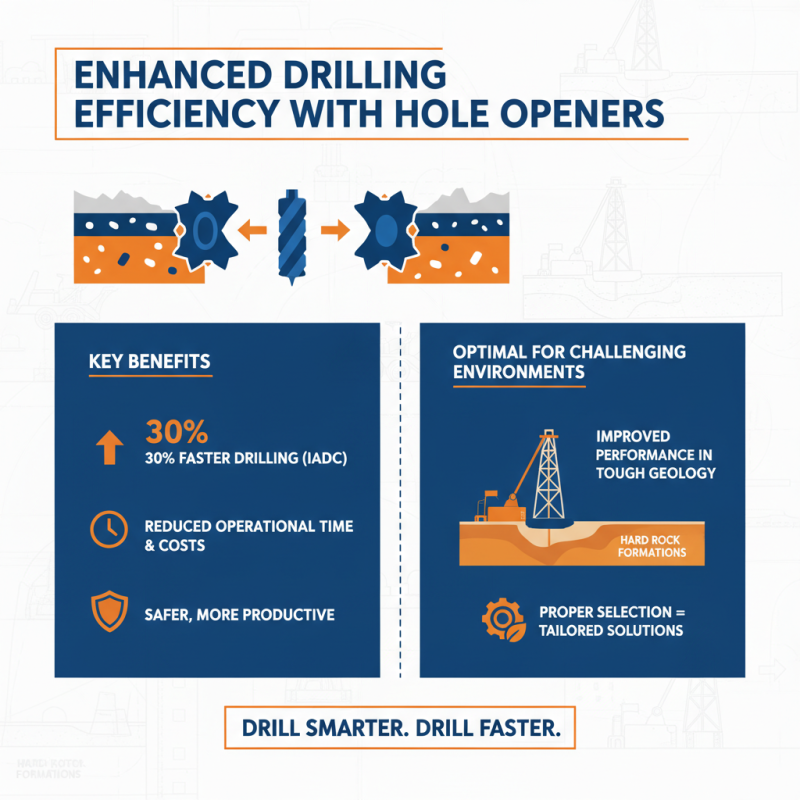

Using hole openers effectively can greatly enhance drilling efficiency across various environments. According to the International Association of Drilling Contractors (IADC), utilizing the right hole opener can improve drilling speed by up to 30%, significantly reducing operational time and costs. This efficiency is paramount, particularly in challenging environments such as hard rock formations where traditional drill bits might struggle. Proper selection and application of hole openers tailored to specific geological conditions can lead to safer and more productive drilling operations.

In challenging drilling scenarios, employing techniques such as adjusting the weight on bit (WOB) and rotation speed is crucial for maximizing the performance of hole openers. A report from the Society of Petroleum Engineers (SPE) indicates that optimizing these parameters can result in a 25% increase in penetration rates in difficult formations. Additionally, the use of reamers in conjunction with hole openers can help maintain borehole stability, allowing for smoother drilling and minimizing the risk of stuck pipes. By understanding the interplay of equipment and drilling techniques, operators can achieve excellent results in diverse environments, from offshore to remote land sites.

When it comes to drilling operations, the efficiency of the process can significantly impact overall productivity and cost-effectiveness. Choosing the right hole opener is essential for achieving optimal performance in various drilling environments. Enhanced drilling efficiency can be attained by employing tools designed to improve penetration rates, reduce torque requirements, and minimize wear and tear on equipment. This focus on efficiency not only leads to faster job completion but also contributes to lower operational costs.

Several types of hole openers excel in specific applications, leveraging advanced designs and materials to optimize drilling techniques. A well-selected hole opener can dramatically influence the speed at which boreholes are created, allowing for smoother transitions between different drilling stages. Additionally, features such as adjustable cutting structures and innovative geometries can cater to specific geological conditions, thereby enhancing the adaptability of drilling operations. By prioritizing the selection of the right equipment, operators can significantly boost their drilling capabilities and achieve outstanding results in diverse projects.