When it comes to drilling through tough materials, the right tool makes all the difference. Steel Hole Saws are essential for many projects. These tools provide precision and efficiency in cutting through various surfaces, including metal and wood.

Different types of Steel Hole Saws are available, each serving specific needs. For example, some are designed for softer materials, while others are robust enough for hard metals. It’s crucial to choose the right type for your project. Not every Steel Hole Saw is suitable for every situation. Sometimes, mistakes are made in choosing the wrong type, which can lead to frustration.

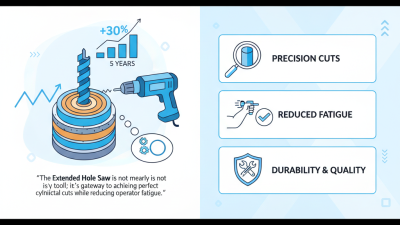

Selecting the best Steel Hole Saw can enhance your work quality. Consider factors like material thickness, cutting speed, and tooth design. Every detail matters when it comes to achieving clean cuts. Reflecting on past projects can help. What worked well? What didn’t? This thought process can guide your next choices. The perfect Steel Hole Saw is out there, waiting to make your project easier.

When considering steel hole saws, it's essential to understand the different types available and their specific applications. Steel hole saws are primarily categorized into various types based on their materials and intended use. High-speed steel (HSS) saws are popular for cutting through thinner materials. Their durability and heat resistance make them suitable for versatile tasks. In contrast, bi-metal hole saws combine toughness with flexibility, making them ideal for cutting through tougher materials like wood and metal. According to industry reports, bi-metal saws are favored for their longevity and performance, cutting up to 30% more holes than HSS saws in certain applications.

Applications vary significantly. For example, plumbing and electrical work often require specific hole saw dimensions. A standard size for plumbing installations is often 2 to 4 inches. However, inadequacies in sizing can lead to inefficiencies. Many users find themselves with holes that are too large or too small. This mismatch can cause frustration during installation. Reports indicate that improper sizing affects up to 25% of projects, reflecting the need for better planning and measurement practices.

In outdoor projects, materials can also complicate the selection. Thin steel might require a different approach than thick hardwood. Experts recommend specific saws tailored to these materials to maximize efficiency. Yet, many still use generic saws, risking ruin on their projects. This mismatch often leads to wasted time and materials, underscoring the importance of choosing the right hole saw type based on application requirements.

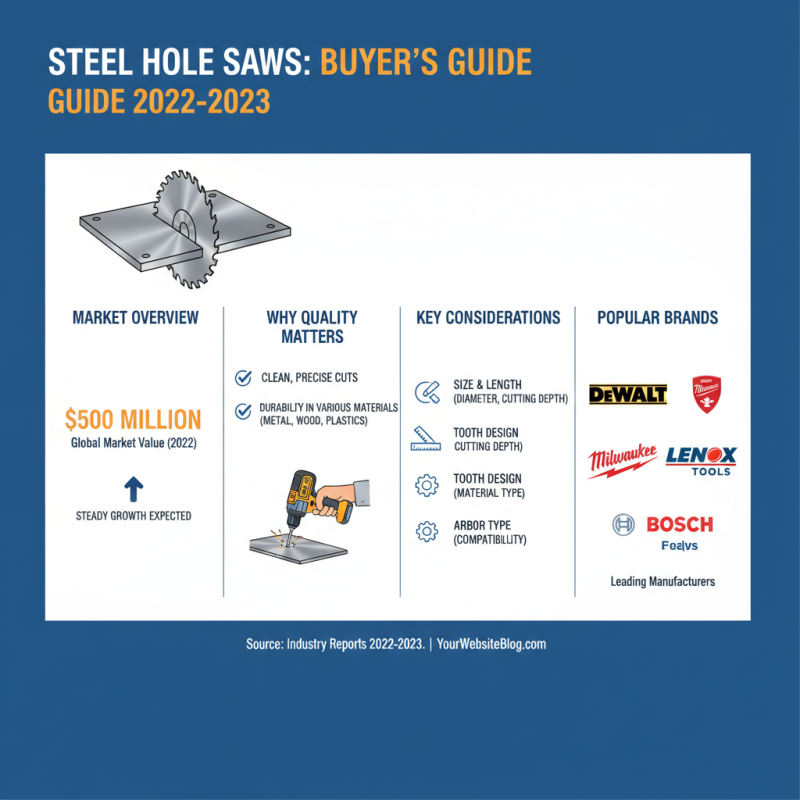

When choosing a steel hole saw, several factors come into play. The material you will be cutting is crucial. Different materials require different hole saw types. For instance, wood and metal require different teeth configurations. Are you working on a woodworking project or a metal fabrication task? Identifying your primary material is essential.

Tip: Always consider the diameter of the hole saw. Larger diameters may provide deeper cuts but can be challenging to control. For precise work, a smaller size is often preferable.

The tooth design also plays a significant role in performance. Carbide-tipped teeth can withstand heat better and last longer. However, they may not be as efficient for softer materials. Think about the longevity you require versus the immediate need for clean cuts.

Tip: Inspect the tooth count. More teeth can yield smoother cuts but may cut slower. Fewer teeth will cut faster but may leave a rough finish. Finding the balance is key. Understanding your specific needs will lead to better decisions. Choose wisely to avoid buyer's regret later down the line.

This bar chart represents the popularity ratings of various types of steel hole saws based on user preferences. These ratings can help guide your selection for your next project.

When it comes to steel hole saws, the material is crucial. Different materials provide distinct benefits and drawbacks. High-speed steel (HSS) is a popular choice for its durability and heat resistance. It can handle various metals and materials, making it versatile. However, HSS might wear out more quickly than other types with heavier use.

Bi-metal hole saws combine HSS with a softer steel, offering enhanced strength. They are robust and can withstand tough jobs. These saws often cut through harder materials more efficiently, but they can be more expensive. Users may find that the added cost reflects on longevity and performance.

Carbon steel hole saws are a budget option. They work well for wood and plastic, but struggle with harder materials. Users often need to replace them frequently after heavy use. They might be suitable for light tasks but can limit your project's scope.

Each material has its place, depending on the work at hand and your budget constraints. Always weigh your options carefully before deciding.

When selecting a steel hole saw for your upcoming project, understanding the popular brands and models is essential. In 2022, the global hole saw market was valued at approximately $500 million and is expected to grow steadily. High-quality steel hole saws are essential for achieving clean and precise cuts in various materials. Models vary significantly in size, length, and design.

Many professionals recommend opting for bi-metal hole saws for their durability and versatility. These models effectively cut through wood, metal, and plastics, making them a favorite among DIYers and contractors alike. Remember, the tooth count on a hole saw affects its cutting efficiency. A higher tooth count results in smoother finishes, while lower counts increase speed.

Tip: Always match the hole saw to your specific material. This ensures efficiency and extends the life of your tool. Annually, tool failures lead to wasted time and resources; consider that before you choose. Also, evaluate user reviews and feedback. These insights reveal common issues that could impact your project. Opting for a well-rated model might save you from frustration later on.

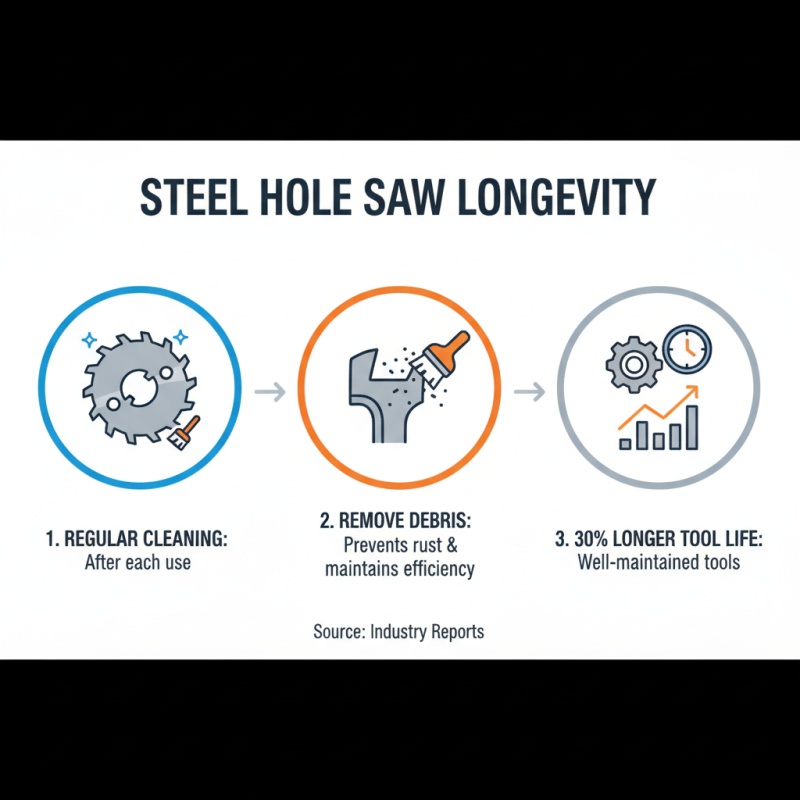

When working with steel hole saws, proper maintenance is crucial for longevity. Reports indicate that well-maintained tools can last up to 30% longer than those neglected. Regular cleaning is essential. After each use, ensure you remove any debris lodged in the teeth. This helps maintain cutting efficiency and prevents rust.

Tip: Always store your hole saws in a dry place. Moisture can lead to corrosion. Utilize a protective case to keep them safe. Periodically inspect the blades for dullness. Dull blades require more force and can lead to tool breakage.

Another point to consider is lubrication. Applying cutting oil can significantly reduce friction and prolong the life of the saw. A study showed that using lubrication during operation increases tool life by up to 50%. However, remember not to overdo it, as excess oil may attract dirt.

Tip: Use the right speed settings for different materials. A slower speed is better for harder materials, while faster speeds work well with softer ones. Experimenting with settings can lead to more efficient cuts.