In the ever-evolving world of construction and renovation, the importance of precision tools cannot be overstated. Among these tools, the Wall Hole Saw has emerged as a critical instrument for achieving efficient cutting and flawless results in various applications, from electrical work to plumbing installations. According to a recent industry report by MarketsandMarkets, the global market for hole saws is anticipated to surpass $350 million by 2025, driven by rising construction activities and the increasing need for specialized tools among professionals. This surge in demand highlights the necessity for both quality and durability in hole saws, particularly in sectors requiring intricate measurements and finishes.

Renowned expert in cutting tools, Dr. James Thompson, emphasizes the significance of choosing the right Wall Hole Saw for each job, stating, "The effectiveness of a Wall Hole Saw directly correlates to not just the time saved, but also to the accuracy and quality of workmanship one can achieve." This underscores the pivotal role that these saws play in ensuring that the end results meet the highest industry standards. With myriad options available, selecting the top models equipped with the latest innovations can drastically improve efficiency and output in any project. This article delves into the top 10 Wall Hole Saws currently available, offering insights into their features, benefits, and factors to consider for optimal performance.

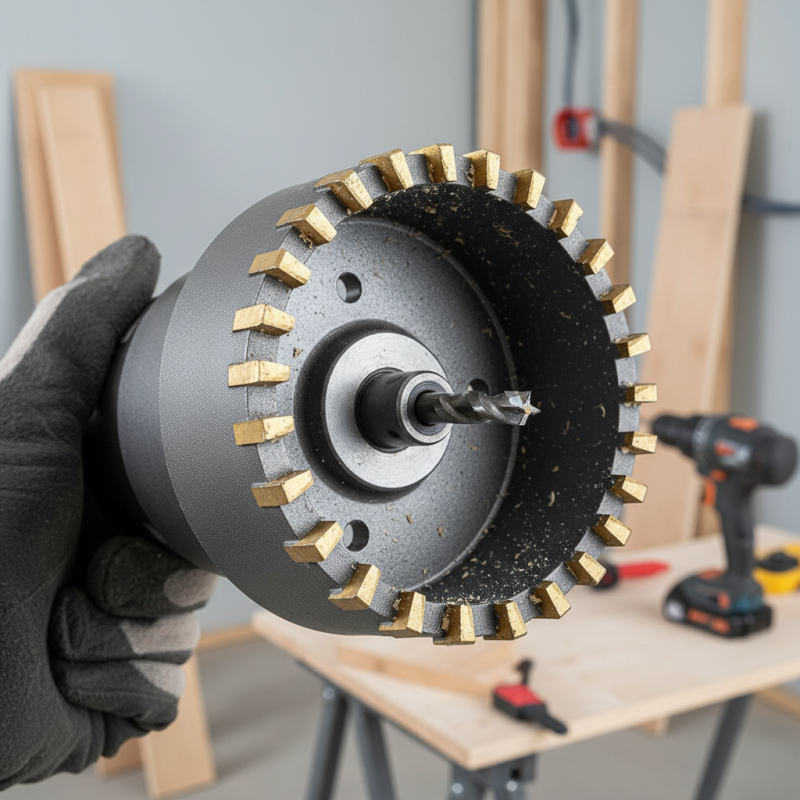

When selecting a wall hole saw, several key features play a crucial role in ensuring optimal performance and efficient cutting. First and foremost, material quality is paramount. High-speed steel (HSS) and carbide-tipped options are popular choices due to their durability and ability to maintain sharpness over extended use. Additionally, the design of the saw teeth can significantly affect the cutting process; aggressive tooth configurations are ideal for faster cuts, while finer teeth provide clean edges, making it essential to choose the right design based on your project requirements.

Another crucial feature to consider is the size variety available in a wall hole saw set. A versatile set that includes multiple sizes will allow you to tackle various tasks without needing to purchase additional tools. Furthermore, an essential consideration is the compatibility of the hole saw with your drill type. Some models may require specific drill attachments or adapters, so ensuring that your drill can accommodate the chosen hole saw will save time and effort during installation. With these factors in mind, you can select the most suitable wall hole saw for your cutting needs, resulting in perfect results every time.

When selecting a hole saw, understanding material compatibility is crucial for ensuring efficient cutting and achieving perfect results. Different materials require specific types of hole saws to optimize performance and durability. For instance, bi-metal hole saws are ideal for cutting through metals and hardwoods, whereas carbide-tipped hole saws are better suited for masonry and ceramic tiles. According to industry reports, using the right hole saw can increase cutting efficiency by up to 30%, significantly reducing project time and material waste.

Tips for choosing the right hole saw include assessing the hardness of the material you’ll be cutting. For softer woods, standard high-speed steel (HSS) hole saws often suffice. However, when working with more rigid materials, investing in carbide or bi-metal options is recommended. Additionally, consider the diameter of the hole saw; larger holes may require more substantial power tools to maintain control and accuracy.

Another critical factor is the thickness of the material. Hole saws designed for thicker materials often have larger teeth and deeper cuts to accommodate the extra depth. It’s essential to match the hole saw to both the thickness and hardness of the material for optimal performance. This attention to detail can enhance the overall quality of the work and prolong the lifespan of your equipment.

When selecting the best wall hole saws for efficient cutting, understanding the different blade types is crucial. Carbide teeth saws are renowned for their durability and ability to cut through tough materials, making them ideal for heavy-duty applications. These saws can withstand heat and wear, ensuring that they maintain sharpness over extended use. Their ability to slice through wood, drywall, and metal with ease makes them a go-to choice for professionals and DIY enthusiasts alike.

On the other hand, bi-metal hole saws combine the best features of both steel and high-speed steel. This hybrid design allows them to be flexible and resistant to breakage while also being capable of cutting through various materials, including harder metals. Bi-metal saws are versatile, making them suitable for a range of projects. Finally, diamond hole saws are specialized tools that offer exceptional performance for cutting through tile, concrete, and stone. The diamond grit enhances durability and cutting speed, providing a clean and precise cut. Each blade type brings unique advantages to the table, and understanding these can help users make informed decisions tailored to their specific cutting needs.

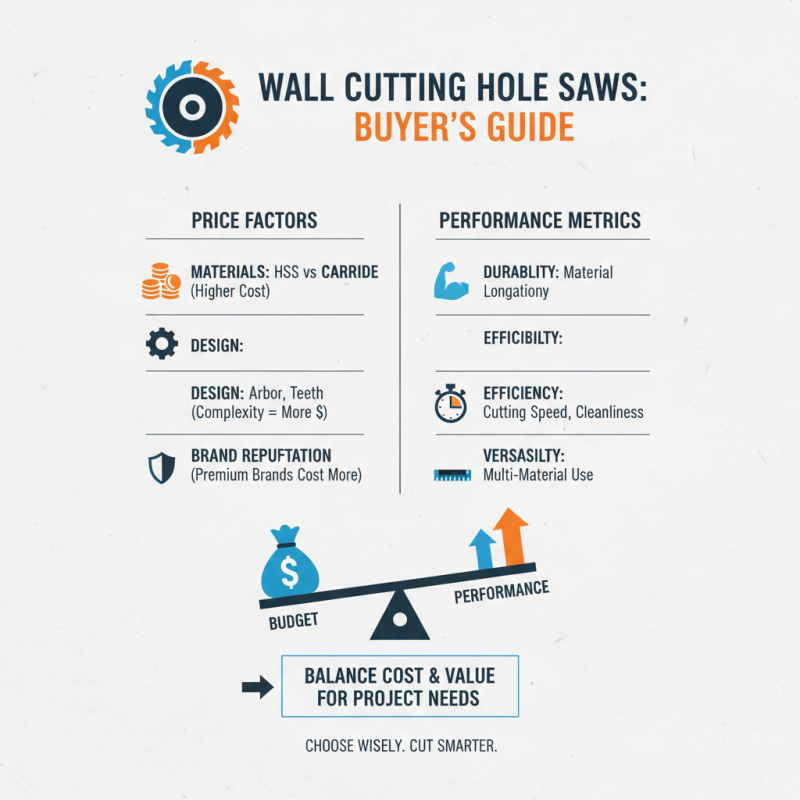

When selecting the right hole saws for wall cutting, understanding the industry standards for pricing and performance metrics is crucial. The cost of hole saws can vary significantly based on materials, design, and brand reputation. Generally, professional-grade hole saws made from high-speed steel or carbide-tipped materials are priced higher due to their durability and efficiency. It is essential for contractors and DIY enthusiasts alike to balance their budget with the performance they need for specific applications, ensuring that they choose options that offer both longevity and value.

Performance metrics include factors such as cut speed, hole size accuracy, and operational ease. The best performing hole saws typically demonstrate quick penetration in various materials without causing excessive wear. Additionally, user reviews and feedback are critical indicators of real-world effectiveness. A saw that excels in making clean, precise cuts with minimal burring tends to be favored in the industry. By focusing on these pricing and performance standards, users can better navigate the options available and select the top hole saws that meet their cutting demands efficiently.

When using wall hole saws, safety precautions are paramount to ensure both effective cutting and user protection. First and foremost, it is crucial to wear appropriate personal protective equipment (PPE), including safety goggles, ear protection, and a dust mask. These items safeguard against flying debris, excessive noise, and inhalation of harmful dust particles generated during the cutting process. Additionally, securing the work area to prevent unauthorized access while cutting can help avoid accidents.

Before starting the cutting process, it's essential to check that the wall is free of electrical wires and plumbing. Using a stud finder can assist in locating these hidden hazards. Furthermore, marking the cutting area clearly and securing the saw firmly in place helps maintain precision. It is also advisable to start the hole saw at a low speed, gradually increasing it to avoid overheating and ensure a cleaner cut. Regularly checking the saw's condition and replacing dull blades can significantly enhance performance and maintain safety standards during use.

| Model | Material | Size (inches) | Cutting Depth (inches) | Recommended RPM | Best Features |

|---|---|---|---|---|---|

| Model A | Carbon Steel | 2 | 1 | 2000-3000 | Durable, Fast cutting |

| Model B | Bi-Metal | 3 | 1.5 | 1800-2800 | Heat-resistant, Versatile |

| Model C | Carbide Tipped | 4 | 2 | 2200-3200 | Long-lasting, High precision |

| Model D | High-Speed Steel | 2.5 | 1 | 2100-3100 | Sharp edges, Easy to use |

| Model E | Diamond Coated | 5 | 2.5 | 2500-3500 | Ideal for hard materials, High durability |