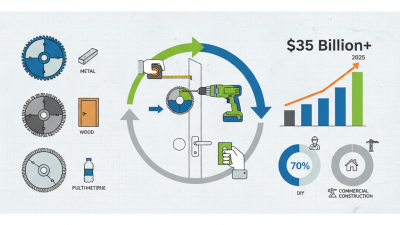

In the realm of construction and DIY projects, the "Extended Hole Saw" has become an invaluable tool for professionals and hobbyists alike. According to industry reports from the National Tool Manufacturers Association (NTMA), the demand for advanced drilling solutions has surged by over 30% in the past five years. This trend highlights the necessity for versatile tools that can handle materials of varying densities and thicknesses efficiently. As drilling technologies advance, understanding the capabilities and best practices for using extended hole saws becomes essential for achieving precision and durability in every task.

Renowned drilling expert Dr. Thomas Hale emphasizes the importance of utilizing the right tools for optimal results: “The Extended Hole Saw is not merely a tool; it’s a gateway to achieving perfect cylindrical cuts while reducing operator fatigue.” His insights reflect a growing acknowledgment within the industry that investing time in mastering these tools significantly impacts overall project quality. This guide aims to provide comprehensive tips, techniques, and insights into maximizing the potential of the Extended Hole Saw, ensuring that users can drill with confidence and efficiency, whether on the job site or at home.

Extended hole saws are essential tools for achieving precise and clean cuts in various materials, ranging from wood to metal and even masonry. These saws have longer pilot drills that allow for deeper cutting depths, making them particularly useful for tasks that involve thick materials or require the creation of larger diameter holes. According to a report by the Tool and Hardware Manufacturers Association, the demand for extended hole saws has surged by over 30% in the past five years, highlighting the growing acknowledgment of their versatility in both professional and DIY projects.

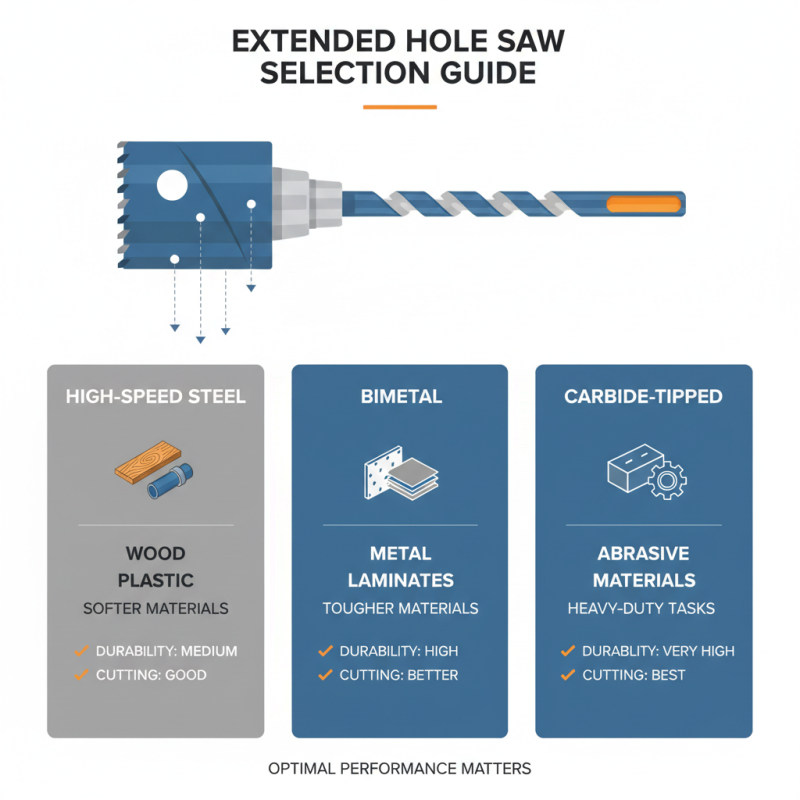

When considering the types of extended hole saws available, it is essential to understand their specific applications. High-speed steel (HSS) saws are well-suited for softer materials like wood and plastic, while carbide-tipped saws excel in cutting through harder substances such as stainless steel and ceramics. Recent studies show that using the appropriate type of hole saw can increase cutting efficiency by up to 40%, translating to significant time and cost savings in construction and manufacturing. Additionally, the rise in home improvement projects has propelled the expansion of the extended hole saw market, evidencing their crucial role in achieving precise drilling results and enhancing overall productivity.

When selecting an extended hole saw, there are several key factors that should guide your decision to ensure optimal performance. First and foremost is the material of the hole saw itself. Extended hole saws are typically constructed from high-speed steel, bi-metal, or carbide, each offering different levels of durability and cutting efficiency. High-speed steel is a common choice for softer materials like wood and plastic, while bi-metal options provide a blend of toughness and flexibility, making them suitable for tougher materials such as metal or laminates. Carbide-tipped saws, on the other hand, are ideal for abrasive materials and heavy-duty tasks.

Another critical consideration is the diameter of the hole saw. Extended sizes come in various diameters, which means you should align your choice with the specific project requirements. A larger diameter will allow for bigger holes but can be harder to control, whereas smaller diameters are easier to handle but may not suit your project needs. Additionally, consider the slot design for chip removal. An effective slot design can significantly enhance performance by allowing debris to escape during drilling, preventing overheating and clogging, ultimately leading to cleaner results.

When preparing to drill with extended hole saws, proper preparation is key to achieving optimal results. Before you begin, ensure you have the right materials for the job. Choosing the appropriate hole saw size based on the thickness of the material and the diameter of the hole required is crucial. According to industry reports, using extended hole saws can reduce drilling time by up to 30%, enabling more efficient workflows when cutting through thicker materials.

Tip: Always mark the drilling spot clearly and use a center punch to create a starter hole. This prevents the drill bit from wandering, ensuring precision in your work. Additionally, it's advisable to use cutting oil during the process to prolong the lifespan of your hole saw and maintain cutting efficiency. Research indicates that applying lubrication can decrease wear and heat buildup, resulting in cleaner cuts.

Furthermore, maintaining a steady hand and a consistent speed while drilling can significantly enhance the outcome. An erratic approach can lead to uneven holes or damage to the material. If you’re drilling multiple holes, consider using a drill press for consistency. Keep an eye on the drill bit's temperature, as overheating can lead to failure. By following these tips and preparing adequately, drilling with extended hole saws can be a much more streamlined and effective process.

Maintaining and caring for your hole saw is crucial to ensure optimal performance and longevity. Regular maintenance can significantly extend the lifespan of your tools. According to a study by the National Tool Association, properly cared-for tools can last up to 50% longer than neglected ones. One effective practice is to clean the hole saw immediately after use. Removing debris and material residues prevents corrosion and buildup that could compromise cutting efficiency in future projects.

Additionally, proper storage plays a vital role in the condition of your hole saw. Keep it in a dry and organized toolbox to avoid exposure to moisture, which can lead to rust. A survey conducted by the American Society of Machinists indicated that nearly 40% of tool failures are due to improper storage. Using a dedicated storage solution, such as a protective case or a magnetic strip, will help maintain sharpness and prevent damage from impacts. Lastly, periodically lubricating the saw with a light oil can improve cutting performance and further protect against wear, ensuring that you achieve perfect drilling results every time.

| Tip | Description | Best Practices |

|---|---|---|

| Choose the Right Size | Select a hole saw that matches the diameter needed for your project. | Always verify the size before starting the drilling process. |

| Use the Correct Speed | Adjust the drill speed based on the material being drilled. | For wood, use higher speeds; for metal, slower speeds are better. |

| Lubricate When Necessary | Applying lubricant can reduce friction and heat. | Use cutting oil for metal materials to enhance hole saw life. |

| Maintain a Steady Pressure | Apply consistent, gentle pressure while drilling. | Avoid excessive force to prevent damaging the hole saw. |

| Clean After Use | Remove debris and clean the hole saw after each use. | Store in a dry place to prevent rust and corrosion. |

When using extended hole saws, avoiding common mistakes can significantly enhance drilling efficiency and quality. One prevalent error is

inadequate speed and feed rate, which can lead to overheating and premature wear of the hole saw. According to a report from the

National Association of Manufacturers, machines operated at optimal speeds can improve tool lifespan by up to 40%. Understanding the material being drilled and

adjusting the speed accordingly is essential; harder materials typically require slower speeds, while softer materials allow for faster cutting rates.

Another frequent mistake is insufficient coolant application during the drilling process. Effective cooling reduces friction and heat build-up,

which can damage both the hole saw and the workpiece. A study by the Society of Manufacturing Engineers highlights that applying coolant not only extends

tool life but also enhances cut quality, resulting in a 20% reduction in surface roughness. Ensuring that a proper cooling method is in place, whether through misting or flood cooling systems, is

key to achieving clean and precise holes. By being mindful of these common pitfalls, users can maximize the performance of their extended hole saws and achieve

perfect drilling results consistently.