In the ever-evolving landscape of drilling technologies, Alloy Hole Openers have emerged as indispensable tools in maximizing drilling efficiency and minimizing operational costs. According to a recent report by Global Market Insights, the global drilling equipment market is projected to reach $60 billion by 2027, with specialized tools like Alloy Hole Openers playing a pivotal role in this growth. These advanced tools, made from high-performance alloys, facilitate precision drilling in various applications, significantly improving penetration rates and extending the lifespan of drilling bits. As the demand for effective and efficient drilling solutions rises, understanding the potential of Alloy Hole Openers becomes crucial for industry professionals aiming to enhance their operational success. This comprehensive guide will delve into the best practices for utilizing Alloy Hole Openers effectively, ensuring that operators can leverage their full potential in the field.

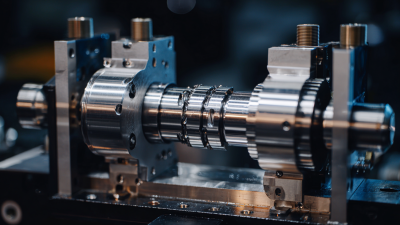

Alloy hole openers are essential tools in the drilling industry, designed to optimize drilling performance while reducing operational costs. Understanding their key features can greatly enhance efficiency and improve outcomes. These tools are primarily known for their durability and resistance to wear, which makes them ideal for challenging geological conditions. The unique alloy composition provides enhanced strength and the ability to withstand higher temperatures and pressures, making them suitable for a range of applications.

Alloy hole openers are essential tools in the drilling industry, designed to optimize drilling performance while reducing operational costs. Understanding their key features can greatly enhance efficiency and improve outcomes. These tools are primarily known for their durability and resistance to wear, which makes them ideal for challenging geological conditions. The unique alloy composition provides enhanced strength and the ability to withstand higher temperatures and pressures, making them suitable for a range of applications.

When using alloy hole openers, consider the following tips: First, always ensure the tool is correctly aligned with the drilling path to minimize resistance and extend tool life. Second, maintain consistent drilling parameters, such as weight on bit and rotary speed, to achieve optimal cutting performance. Lastly, regular monitoring of the tool’s condition can help identify wear patterns early, allowing for timely replacements or adjustments.

In addition to these operational strategies, the advantages of alloy hole openers include their ability to provide a smoother hole finish and improved rate of penetration (ROP). The efficiency of these tools translates into time savings and reduced costs in the long term, making them a valuable investment for any drilling operation.

The use of alloy materials in hole openers has revolutionized drilling efficiency and performance. Alloys, primarily made from a mixture of metals, bring forth characteristics that are often superior to those of singular metal types. The inclusion of elements like nickel, chromium, and molybdenum enhances the overall strength, durability, and resistance to wear and corrosion. This is particularly important in demanding drilling environments where the materials are subjected to extreme stresses.

In addition to their physical robustness, alloy hole openers also exhibit improved thermal performance. The unique composition of alloys allows them to dissipate heat more effectively, reducing the risk of overheating during operation. This not only prolongs the lifespan of the tools but also ensures a smoother drilling process. Understanding the science behind these materials facilitates better decision-making for operators seeking to maximize efficiency while minimizing downtime. By leveraging the advantages of alloy hole openers, companies can achieve greater productivity and cost-effectiveness in their drilling operations.

| Material Type | Density (g/cm³) | Tensile Strength (MPa) | Hardness (HV) | Thermal Conductivity (W/m·K) | Corrosion Resistance |

|---|---|---|---|---|---|

| Aluminum Alloy | 2.7 | 200-250 | 60-150 | 205 | Good |

| Stainless Steel Alloy | 7.9 | 500-700 | 150-250 | 16 | Excellent |

| Titanium Alloy | 4.5 | 900-1200 | 200-400 | 7 | Very Good |

| Nickel Alloy | 8.9 | 600-1000 | 200-350 | 13 | Excellent |

When it comes to maximizing the efficiency of alloy hole openers, understanding best practices is crucial for both minimizing costs and enhancing overall performance. According to a report from the International Association of Drilling Contractors (IADC), integrating high-quality alloy hole openers can improve drilling efficiency by up to 30%. This significant improvement is largely attributed to the advanced metallurgy and design of these tools, which provide superior durability and penetration rates compared to traditional options.

One essential practice for using alloy hole openers effectively is ensuring that the right size and type are selected based on the specific geological conditions of the drilling site. A study by the Society of Petroleum Engineers (SPE) indicated that mismatched hole openers can lead to a 25% increase in wear and tear, consequently extending drilling times and incurring additional costs. Additionally, regular maintenance and checks on the openers can prevent unexpected downtimes, as worn-out bits account for nearly 40% of non-productive time in drilling operations. Adhering to these best practices not only optimizes the use of alloy hole openers but also significantly contributes to more sustainable and cost-effective drilling operations.

When it comes to drilling, choosing the right tool can significantly impact efficiency and outcomes. Alloy hole openers have emerged as a superior alternative to traditional tools for various applications. Their advanced material composition makes them more durable, allowing for deeper and more precise holes without the risk of overheating or dulling. This durability translates to less frequent tool changes and reduced downtime, ultimately enhancing productivity on the job site.

**Tip:** Always match your alloy hole opener to the specific type of material you are working with. Understanding the properties of both the opener and the material can prevent premature wear and improve overall performance.

Another key advantage of alloy hole openers is their lightweight design, which grants users better control and maneuverability. Unlike traditional tools, which can be cumbersome and exhausting to handle over extended periods, alloy options allow for smoother operation and less physical strain. This is especially beneficial when working in tight or awkward spaces, where precision matters.

**Tip:** Regularly inspect your alloy hole openers for any signs of wear or damage. Maintaining your tools not only extends their life but also ensures they operate at peak efficiency when you need them most.

This chart compares the efficiency of Alloy Hole Openers against traditional tools across various dimensions such as Efficiency, Durability, Cost Effectiveness, Ease of Use, and Maintenance. As observed, Alloy Hole Openers tend to outperform traditional tools in most aspects, highlighting their effectiveness in modern drilling operations.

Proper maintenance of alloy hole openers is essential for ensuring their longevity and efficiency. Regular inspection for wear and tear can help identify potential issues before they become significant problems. Look for signs of dullness on the cutting edges; if the edges appear rounded or chipped, it's time to sharpen or replace the opener. Additionally, ensure that the lubrication is sufficient; a well-lubricated tool will operate more smoothly, reducing friction and preventing overheating during use.

Cleaning your alloy hole openers after each job is another crucial practice. Remove any debris or built-up material that may adhere to the surface. This not only keeps the tool in optimal working condition but also prevents contaminants from affecting the performance of the next job. Store the tools in a dry, rust-free environment to further protect them from corrosion. Implementing these maintenance tips can significantly extend the lifespan of your alloy hole openers, allowing for more efficient usage and improved results in your projects.