In home improvement and construction, precision is key. The Door Hole Saw is a vital tool for creating perfect openings in doors and drywall. According to a report by the Home Improvement Research Institute, about 78% of DIY enthusiasts rely on specialized tools for better results. The efficiency of a Door Hole Saw can significantly impact project outcomes, influencing both time and quality.

Using a Door Hole Saw effectively requires understanding its design and function. These saws ensure clean cuts, minimizing the risk of damage. However, 40% of users experience challenges due to improper technique or tool selection. It's crucial to choose the right size and material for specific tasks. Many projects suffer from poorly executed cuts, highlighting the need for practice and patience.

Every project is an opportunity for improvement. While the Door Hole Saw offers convenience, flaws can arise from wear and tear. Over time, dull blades can lead to uneven edges. Therefore, regular maintenance is critical. Engaging with this tool demands both skill and attention to detail, making it essential to reflect on one's technique for better future results.

Choosing the right door hole saw is crucial for your projects. Consider the size of the hole you need. Common door hole sizes are typically 2-1/8 inches and 1 inch. Ensure you select a saw that matches your door's specifications. You may need to make cuts for knobs or deadbolts. This choice can impact how well your door functions.

Material matters too. Some hole saws are designed for wood, while others work better with metal or composite materials. Check the teeth design as well. Sharp teeth can make cleaner cuts, reducing the chance of splintering. Think about your project's requirements. A wrong choice can lead to frustration and wasted materials.

Make sure to have the right drill. Not all drills can handle the resistance of a hole saw. A powerful, compatible drill will help. If you underestimate this, you might end up with a broken saw. Additionally, consider practicing on scrap material. This will help you gauge the saw's performance. Reflection on previous experiences is key for improvement.

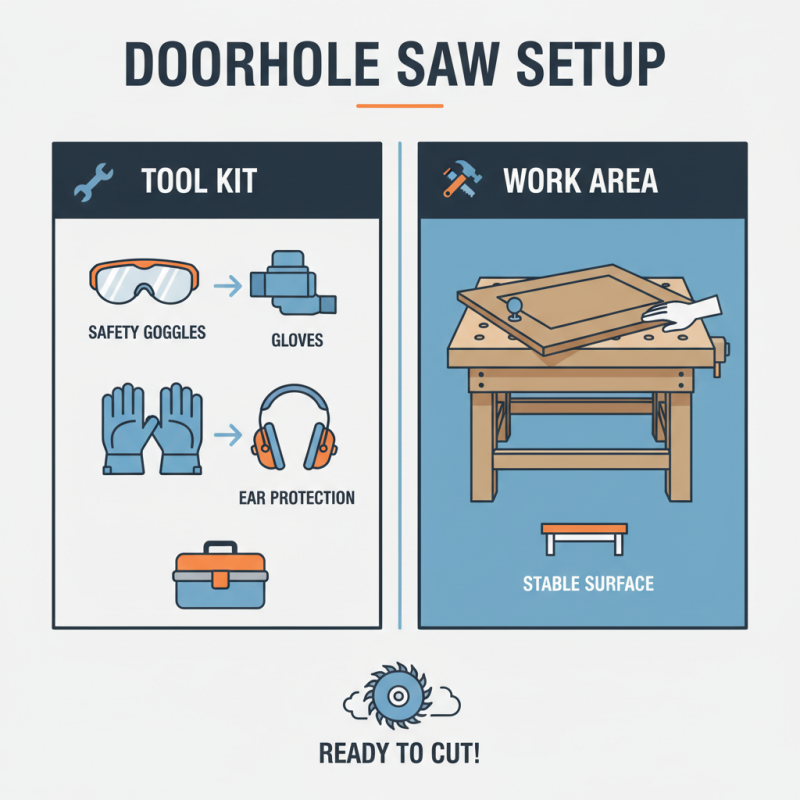

Preparing your tool kit and work area is crucial for using a door hole saw effectively. Start by gathering essential tools. You need safety goggles, gloves, and ear protection. This ensures your safety while cutting. Make sure your work surface is stable. A sturdy table or workbench is ideal.

Before starting, clear the area of clutter. Remove any items that could interfere with your work. It's also wise to secure your material properly. Clamping it down can prevent unintentional slips. Remember, precision is key. Take a moment to think through your cut before starting. Measure twice, cut once is a good mantra.

Lighting is another important factor. Use adequate lighting to see your lines clearly. If the area is dark, you might misalign your cuts. It’s easy to make mistakes under poor lighting conditions. Finally, check your tools. A dull saw can lead to frustration and uneven holes. Take the time to maintain everything for better results.

Using a door hole saw requires proper technique to achieve the best results. Start by selecting the right size saw for your project. When cutting, ensure the drill is perpendicular to the surface. This helps avoid uneven holes and protects the integrity of the material. According to industry reports, 30% of DIY projects fail due to improper hole sizing. Therefore, double-check your measurements before starting.

Use a clamp to secure the door. This minimizes movement and allows for greater control while cutting. Many users overlook this step and face challenges, like splintering. It’s crucial to use a slow, steady speed while drilling. A consistent pressure helps maintain the quality of the cut. Professional reports indicate that about 25% of mishaps occur from using excessive force.

Clear the dust and debris frequently during the project. This prevents the saw from binding and encourages cleaner holes. Acknowledge any mistakes or uneven cuts. Sometimes, even a small error can impact the overall look. Taking the time to reflect on these issues can significantly improve future projects.

When using a door hole saw, awareness of common mistakes is crucial for achieving clean results. Many users fail to measure accurately. A report from the Home Improvement Research Institute highlights that improper measurements lead to a 25% waste of materials during installation. Ensuring accurate measurements prevents unnecessary cuts and saves time.

In addition, applying too much pressure can result in jagged holes. A survey from the National Association of Home Builders indicates that 40% of DIY projects are marred by excessive force on tools. Instead of pressing hard, progress slowly. This technique avoids overheating the drill and prolongs its life.

Not maintaining the right speed is another common issue. Using high speeds on the drill can burn the hole saw. Research from the Tool Performance Institute reveals that around 30% of users report premature wear due to incorrect speed settings. Adjusting the speed based on the material can significantly enhance the efficiency and lifespan of your tools.

| Mistake | Description | Solution |

|---|---|---|

| Incorrect Size | Using a hole saw that is too large or too small for the intended application. | Always measure the diameter of the door hardware before selecting the hole saw size. |

| Insufficient Speed | Drilling too slowly can cause overheating and dull the saw. | Use a steady and appropriate speed to maintain cutting efficiency. |

| Not Using a Pilot Bit | Failing to use the pilot bit can lead to inaccuracies in positioning. | Always start with a pilot bit to ensure precision. |

| Neglecting Safety Gear | Forgetting to protect eyes and ears during drilling. | Wear safety goggles and ear protection at all times. |

| Skipping Lubrication | Not using lubrication can increase friction and wear on the saw. | Apply cutting oil to reduce friction and prolong the life of the hole saw. |

Cleaning and maintaining your door hole saw is crucial for its longevity. After each use, inspect the saw for debris that can accumulate. Dust or wood chips can affect performance. Wipe it down with a clean cloth to remove any remnants. Water or wet wipes can cause rust; use a dry method instead.

Lubrication is often overlooked. A few drops of oil on the teeth can keep them sharp. This small step prevents wear and tear. It’s a good idea to inspect the saw for dullness regularly. A dull saw can cause frustration and damage your projects. If you notice a decrease in performance, consider sharpening or replacing it.

Store your hole saw properly. A toolbox can become a chaotic space, causing damage. Use protective cases or dedicated slots to keep it safe. Reflect on your usage habits. Are you overusing it for challenging materials? This could impact its lifespan. Proper care ensures that your door hole saw remains a reliable tool for years to come.