In the ever-evolving landscape of metalworking, the importance of precision tools cannot be overstated. One such tool that has gained significant traction is the hole saw for metal, known for its efficiency and versatility in creating clean, accurate holes.

According to a recent industry report by Grand View Research, the global hole saw market is projected to reach USD 915.6 million by 2027, driven by an increasing demand across various sectors, including construction, manufacturing, and automotive. This surge emphasizes the necessity for high-quality cutting tools that can withstand the rigors of metal fabrication.

Hole saws offer unique advantages over traditional drilling methods, enabling users to tackle a variety of tasks with ease. In this comprehensive overview, we will explore the versatility and applications of hole saws for metal, equipping professionals with the knowledge to optimize their performance in diverse projects.

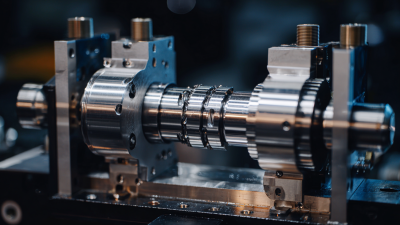

Hole saws play an essential role in metalworking operations, offering unmatched efficiency and precision in cutting holes of various sizes. These tools are specifically designed to create clean, round holes in metal, which is crucial for applications such as HVAC installations, plumbing, and electrical work. Whether you're working with steel, aluminum, or other metals, a quality hole saw ensures that you achieve the desired outcome without damaging the surrounding material.

Hole saws play an essential role in metalworking operations, offering unmatched efficiency and precision in cutting holes of various sizes. These tools are specifically designed to create clean, round holes in metal, which is crucial for applications such as HVAC installations, plumbing, and electrical work. Whether you're working with steel, aluminum, or other metals, a quality hole saw ensures that you achieve the desired outcome without damaging the surrounding material.

When using hole saws, consider the material you’re working with to select the appropriate tooth design and size. For softer metals, a standard high-speed steel (HSS) hole saw suffices, but for harder materials, carbide-tipped options provide enhanced durability. Always use a lubricant to reduce friction, which can prolong the lifespan of the saw and yield smoother cuts.

Additionally, packaging often provides guidance on optimal speed settings for different materials. Following these recommendations can prevent overheating and ensure a more accurate cut. Remember to secure your workpiece firmly before drilling, as this minimizes vibration and keeps your cuts consistent.

When it comes to metal cutting projects, using hole saws offers numerous advantages that enhance efficiency and precision. One of the key benefits of hole saws is their ability to create clean, uniform holes with minimal effort. Unlike traditional drill bits, which may struggle with tougher materials, hole saws can easily penetrate through metals, providing smoother cuts and reducing the need for additional finishing work. This not only saves time but also ensures a professional finish, making them ideal for both DIY enthusiasts and seasoned craftsmen.

Moreover, hole saws come in various sizes and configurations, allowing for versatility in different applications. Whether you are working on plumbing, electrical installations, or custom metalwork, the ability to select the right size hole saw means that one tool can cater to multiple needs. Additionally, advancements in drill technology complement the performance of hole saws, providing the necessary power and battery efficiency to tackle demanding projects without interruption. This combination of benefits underscores why hole saws are becoming a go-to tool for those looking to achieve quality results in metal cutting ventures.

| Dimension | Description | Key Benefits | Typical Applications |

|---|---|---|---|

| Diameter | Available in a range of sizes from 3/4" to 6" | Provides versatility for various cutting needs | Electrical enclosures, metal frames |

| Material Compatibility | Suitable for cutting steel, aluminum, and other metals | Enhances ability to work with various materials | Construction, automotive industry |

| Cutting Depth | Typically ranges from 1" to 2" deep | Allows for drilling deeper holes without needing to change bits | Piping, ventilation systems |

| Material Type | Made from high-speed steel, carbide, or bi-metal | Durable and long-lasting, reducing the need for frequent replacements | Heavy machinery, industrial applications |

| Cutting Speed | Optimized for fast and efficient metal cutting | Increases productivity in metalworking projects | Sheet metal fabrication, general maintenance |

When it comes to hole saws, understanding the different types and their specific applications in metalworking is crucial for achieving optimal results. Hole saws come in various designs, tailored for handling materials from soft metals to the more challenging nickel-based superalloys. The latter, often used in aerospace and high-temperature applications, poses significant challenges due to their toughness. Thus, selecting the right hole saw, designed specifically for such demanding materials, becomes essential for efficiency and precision.

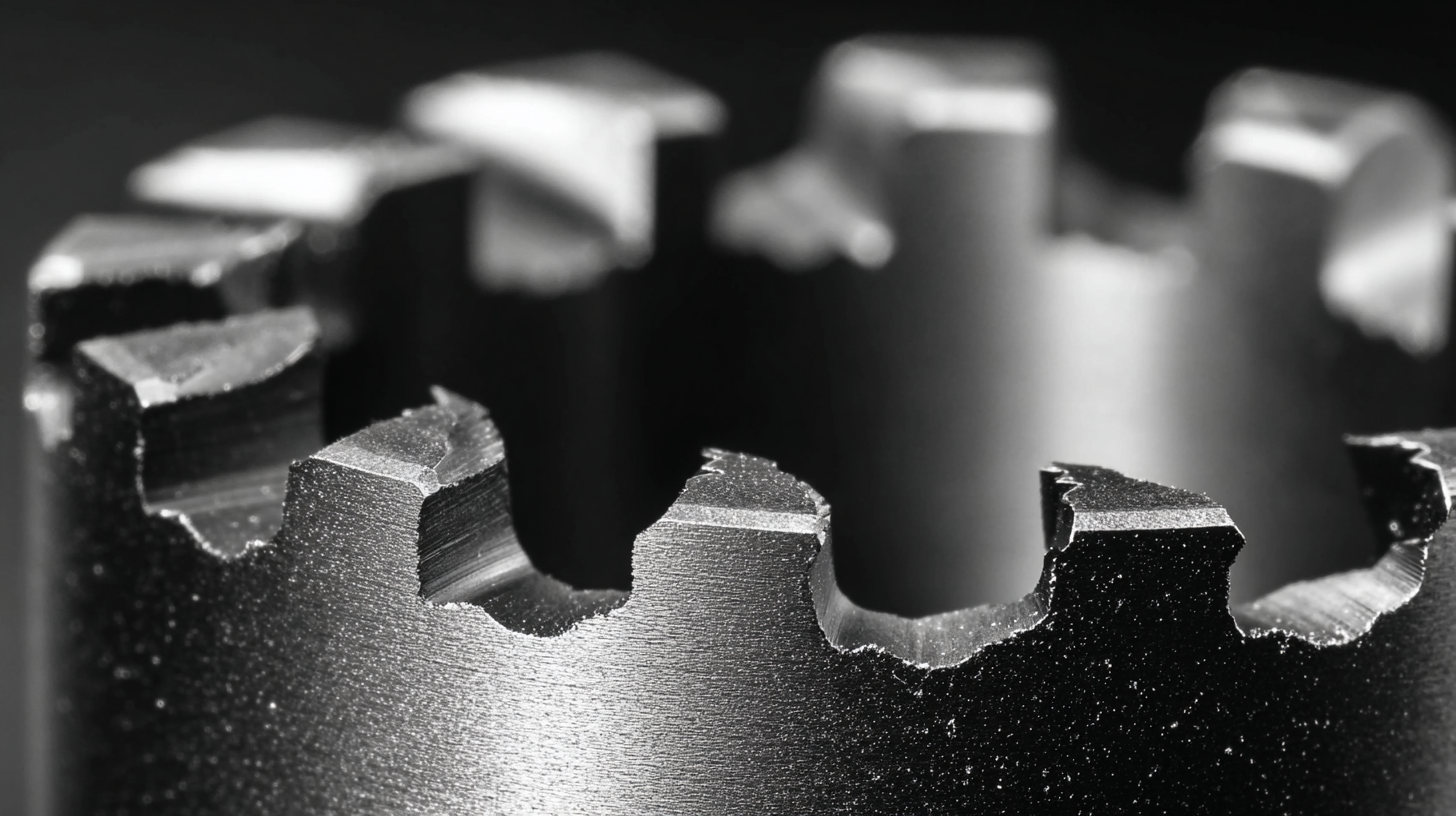

Additionally, the versatility of hole saws extends beyond just the type of metal being cut. Specialized designs can cater to HVAC, plumbing, and electrical installations, where precise cuts are critical. The market offers numerous options, making it vital for professionals to consider their specific needs and the characteristics of the material they are working with. For instance, hole saws with aggressive tooth patterns can enhance cutting performance in harder metals, while other variations might provide smoother and cleaner cuts in softer materials. This understanding empowers tradespeople to choose the right tool for the job, ensuring high-quality outcomes regardless of the metal type.

When tackling metal projects, selecting the right hole saw is crucial for achieving precision and efficiency. The first thing to consider is the material of both the hole saw and the metal you’re working with. Bi-metal hole saws are ideal for tougher metals as they combine flexibility with strength, allowing for clean cuts without damaging the tool. Additionally, the tooth pitch plays a significant role; finer teeth are great for thin metals, while coarser teeth are better for thicker materials.

Another essential factor is the size of the hole saw. It’s vital to ensure that the diameter of the saw matches your project requirements. Investing in a set of various sizes can save you time, providing versatility for different tasks. Finally, don’t overlook the importance of the right arbor; a compatible arbor ensures stability during cutting and reduces the risk of breakage. By keeping these tips in mind, you can streamline your selection process and enhance the success of your metalworking projects.

When it comes to maintaining hole saws, following best practices can significantly extend their lifespan and improve performance. According to a report from the Industrial Metal Cutting Association, properly maintained cutting tools can last 30% longer than those subjected to neglect. Regular inspection and cleaning after each use are crucial steps; ensuring that saw teeth are free from debris and build-up helps maintain cutting efficiency. Additionally, using a cooling lubricant during operations not only reduces friction but can also lower the risk of tooth breakage.

Furthermore, storing hole saws correctly can prevent premature wear. A study by Tooling & Production magazine emphasized the importance of climate-controlled storage, as excessive humidity and temperature fluctuations can lead to rust and deterioration of the cutting edges. It’s advisable to keep hole saws in protective cases and use anti-corrosive coatings when suitable. Adhering to these maintenance protocols will not only enhance the tool's performance but also ensure that it remains a valuable asset in any metalworking environment.